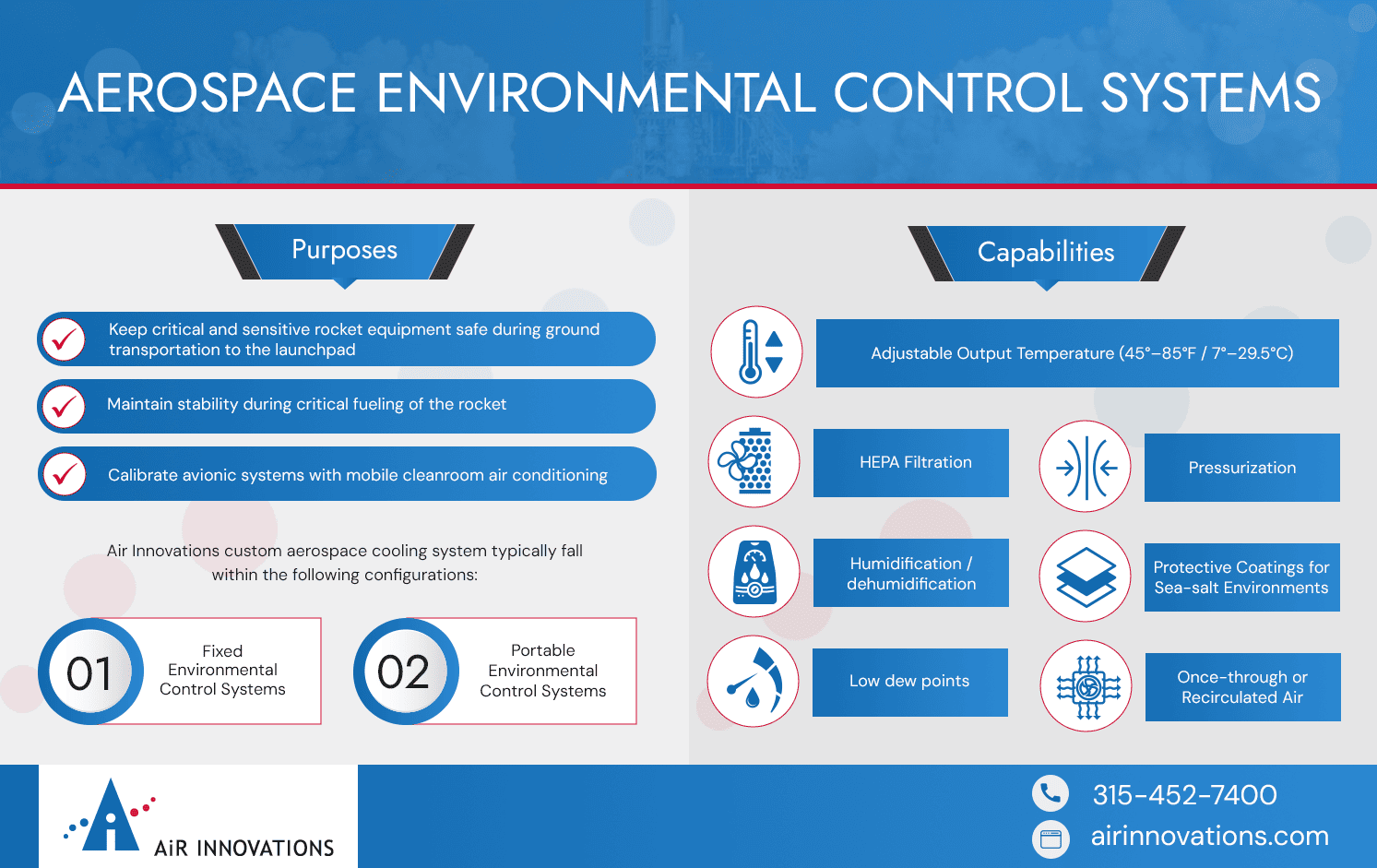

Aerospace Pre-Launch HVAC/Environmental Control Systems

Aerospace pre-launch environmental control systems protect highly sensitive equipment during mission-critical processes prior to the spacecraft being launched into space. In these applications, even a minuscule temperature or humidity variation or failure in filtration can result in mission failure.

Typically, aerospace companies come to us needing environmental control systems during one of these processes:

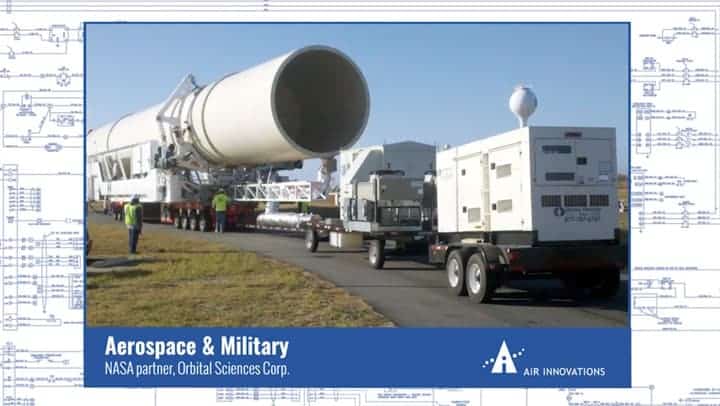

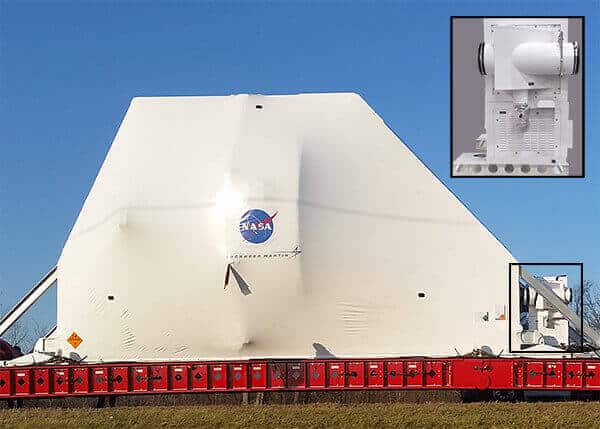

- Keeping critical and sensitive rocket equipment – generally payloads – safe during ground transportation to the launchpad.

- Maintaining stability during critical fueling of the rocket.

- Calibrating avionic systems with mobile cleanroom air conditioning.

- Manufacturing of aerospace equipment in cleanrooms.

To establish the conditions required for these processes, Air Innovations develops environmental control solutions according to precise aerospace specifications. Our pre-launch HVAC systems are customized to adhere to critical filtration, temperature, and humidity requirements, even when operating in harsh environments.

Custom Aerospace Cooling Systems Built to Your Specifications

Keeping payloads properly conditioned before launch requires custom-developed solutions. Each project must adhere to its own unique ambient temperature ranges, air quality requirements, and other specifications. To meet these needs, Air Innovations takes the time to thoroughly understand your project and its requirements.

During the initial stages of your project, we will discuss some basic considerations:

- Temperature and humidity ranges (both ambient and desired conditions)

- Required cleanliness

- Volume of airflow

- Electrical inputs

- Degree of salt air and UV exposure that can affect the equipment’s external parts

- Transportation method

Our pre-launch HVAC systems meet a variety of stringent requirements, including low dew points, one-through or recirculated air, protective coatings for corrosive environments, HEPA filtration, adjustable output temperature, and other needs.

Fixed and Portable Environmental Control Systems

Air Innovations designs both portable environmental control systems (PECS) and fixed environmental control systems for the aerospace industry. These solutions can be designated to facilitate anything from pre-launch payload cooling to serving as a self-contained cleanroom air conditioning unit for calibrating avionic systems.

There are several notable differences between portable and fixed environmental control systems: