When it comes to environmental control requirements, no two industries, companies, or applications are the same. Our customers often struggle to find environmental control units (ECUs) robust and sophisticated enough to maintain precise temperatures, humidity, pressure, and cleanliness in a way that meets their unique requirements. That’s why we’re here.

From homeland security and semiconductors to military and aerospace, Air Innovations designs and manufactures world-class custom ECUs tailored to your industry’s standards and to the specific needs of your application.

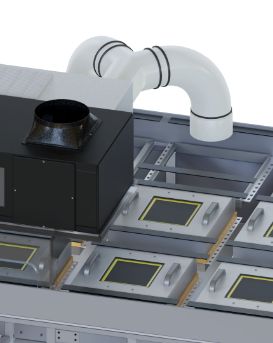

Some customers have specialized equipment or components requiring pristine environmental conditions or certain processes requiring a controlled environment. We build one-off custom solutions for complex applications, custom systems designed for repeat builds, or projects that will be part of larger environmental control systems.

Here are examples of areas in which we’ve helped our customers overcome challenges with custom ECU solutions:

- Pharmaceutical research and manufacturing

- Research and development laboratories

- Hospital laboratories

- Material handling

- Injection molding

- Process manufacturing

- Advanced engineering projects (observation wheels)

We also have deep experience with Class 1 Div. 1 and Class 1 Div. II explosion-proof environmental control units.

To account for a wide range of different applications, our custom ECUs are available in three configurations:

- Integrated– These units accommodate existing equipment structures, resulting in a smaller footprint, greater system efficiency, and lower installation costs.

- Mounted– These units are attached to an existing system and can reduce a system’s overall weight and footprint.

- Standalone– These units are placed around equipment rather than in or on them, allowing for greater flexibility regarding system location, installation, configuration, and performance capabilities.