HEPAir® cleanroom HVAC units, which are available in horizontal modules, are the perfect solution for stable control of temperature, humidity, pressure, and cleanliness. HEPAir integrated modular environmental control systems can be used in cleanrooms as well as in industrial and commercial applications such as compounding pharmacies, laboratories, hospitals, facility additions, mini-environments, and process isolators. Units are ideal for softwall, single-pass air cleanrooms where comfort cooling is desirable. Multiple HEPAir units are easily grouped together for added cooling capacity.

Let’s talk about what HEPAir systems can do for your next project.

The HEPAir system can be applied a variety of different of cleanroom applications as shown below:

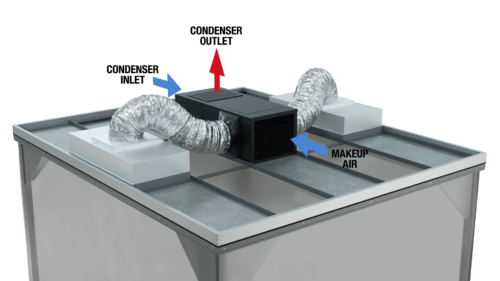

Once-Through Application

The HEPAir unit will continuously supply conditioned air without recirculation, ensuring a constant flow of clean air to maintain desired conditions in the cleanroom.

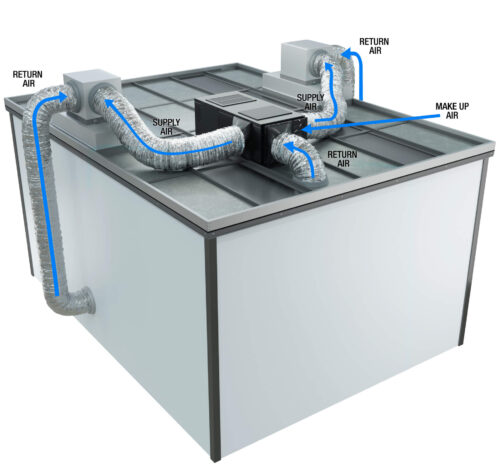

Ducted Recirculation System Application

A cleanroom ducted recirculation system is a specialized ventilation system designed for controlled environments, utilizing a HEPAir unit and HEPA fan filter units to recirculate filtered air, maintain precise temperature and humidity, and minimize contaminants within a cleanroom facility.

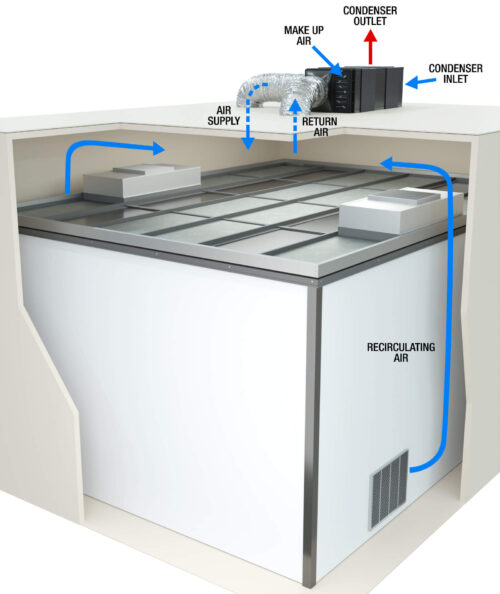

Negative Pressure Plenum Application

In a negative pressure plenum, HEPA Fan Filter units provide the recirculation airflow and the HEPAir provides a conditioning loop to control Temperature and Humidity.

Cleanroom HVAC

HVAC stands for heating, ventilation, and air conditioning, and refers to systems used to control and modify indoor environments in everything from offices and houses to cars and airplanes. In cleanrooms, specialized HVAC systems play an integral role in the regulation of temperature, humidity, pressure, and air quality. Unlike the systems used in residential and commercial facilities, cleanroom HVAC systems require an added level of ventilation and filtration.

Cleanroom HVAC systems are often incorporated into mini-environments, process isolators, research laboratories, and hospitals to ensure compliance with industry and government regulations and requirements for cleanliness, temperature, differential pressure, and humidity.

Clean Room HVAC Design Requirements

Cleanroom HVAC systems require different design elements from the standard systems used in everyday settings. Cleanroom ventilation typically requires a much higher rate of air exchange, as well as more advanced filtration and finer temperature, pressure, and humidity control. In addition, HVAC installers and cleanroom builders must take into account the speed and direction of airflow within the space.

In order to ensure optimal cleanroom operation, a variety of cleanroom classifications or ratings have been developed, including ISO ratings 1 through 9. ISO 1 is the most stringent cleanroom classification, while ISO 9 is the least. Classifications for cleanrooms have been developed based on the amount and size of particulate matter that can be measured in the space. HVAC systems designed for each of these classifications must consider filtration levels, airflow, temperature, humidity, differential pressure, and space restrictions.

Understanding Cleanroom Air Filtration

Cleanroom HVAC units typically incorporate high-efficiency, particulate air (HEPA) filters that are used to remove unwanted fine particles from the air, including dust, dirt, and microbes. Clean room HEPA filters are critical to maintaining a sterile environment for research, medical, pharmaceutical, compounding labs, and other applications that require a stable, highly controlled environment.

HEPAir Systems in Your Cleanroom

The HEPAir® system can be mounted directly or remotely to most manufacturers’ fan filters. Units are designed to work with either standard fan filter units (FFU’s) or can be specified with static pressure capabilities for terminal or panel HEPA filters. HEPAir is modular and can be quickly installed, relocated, or added on to. Its multi-panel design allows for variable duct connections making it ideal for plenum, once-through, and re-circulating installations used in soft-wall cleanrooms, upgrades, problematic areas, additions, spot cooling, and process isolators applications. The mechanical components are accessible from the front or through removable access panels for ease of start-up and maintenance.

HEPAir cooling units combine cleanroom air conditioning and HEPA fan/filter technology and do all the things you would expect from a larger, more complex system.

HEPAir Cleanroom HVAC systems features and capabilities:

- Operate independently of large, central systems

- Can control positive and negative pressure

- Are ideal where point-of-use control is required

- Available with many factory-installed options such as close temperature tolerances, alarms and controls

- Designed to match to most existing fan/filter units

- Available in 115,208-230V, 60 Hz; 220-240V, 50Hz

- Designed for once-through or recirculating applications

- Designed to allow field connections from multiple sides

- A “do-it-yourself” solution for when the cost of outside consultants and contractors is prohibitive

- The ability to easily relocate or modify the space at a later date

- Meets USP 797 for compounding pharmacies by ensuring sterile conditions and regulating temperature & humidity

Download HEPAir datasheet

Download HEPAir manual

Interested in a more customizable solution? Visit our AdvancAir Cleanroom HVAC page.

Looking for a solution for a smaller cleanroom? Visit our ArrayAir Cleanroom HVAC page.

Download our Cleanroom whitepaper

Contact Us for Your Cleanroom HVAC Needs

At Air Innovations, we are committed to providing our customers with the highest quality ISO-rated cleanroom HVAC systems. With more than 30 years in the industry, we specialize in the development and fabrication of unique HVAC and air filtration systems for customers in critical industries. Our dedication to innovation allows us to incorporate the latest ventilation technology into our systems, so our customers can rest assured that they have the best specialty air system for any application. To learn more about our HEPAir® cleanroom HVAC systems and other cleanroom products, contact us or request a quote today.