From the very beginning, we adopted a philosophy of continuous growth and improvement. Over the years, this growth has come from both dramatically increased sales and by acquisition – always with a focus on delivering the best possible solutions to our customers.

Clean Room Technology, Inc. is founded by Larry Wetzel. The company built out entire modular cleanrooms. It rapidly grows into an international business with sales in excess of $20 million.

Floratech is established by a local florist and Jim Kelly, who worked with Wetzel on the first modular cleanroom HVAC system. Floratech designs and manufactures refrigerated open display cases to sell cut flowers in supermarket floral departments. This revolutionizes the floral industry, allowing supermarkets to create impulse sales and change the way flowers are sold in the U.S.

Clean Room Technology Inc. is merged with the French company Clestra to form Clestra Cleanroom Technology Inc. Larry becomes chairman and begins building the new US headquarters in North Syracuse, NY. Larry’s son, Mike Wetzel, also starts working for the company, building cleanrooms throughout Europe.

Clean Room Technology, Inc. is founded by Larry Wetzel. The company built out entire modular cleanrooms. It rapidly grows into an international business with sales in excess of $20 million.

Floratech is established by a local florist and Jim Kelly, who worked with Wetzel on the first modular cleanroom HVAC system. Floratech designs and manufactures refrigerated open display cases to sell cut flowers in supermarket floral departments. This revolutionizes the floral industry, allowing supermarkets to create impulse sales and change the way flowers are sold in the U.S.

Clean Room Technology Inc. is merged with the French company Clestra to form Clestra Cleanroom Technology Inc. Larry becomes chairman and begins building the new US headquarters in North Syracuse, NY. Larry’s son, Mike Wetzel, also starts working for the company, building cleanrooms throughout Europe.

Floratech secures a multi-year contract to supply the entire floral department of one of the largest U.S. supermarket chains.

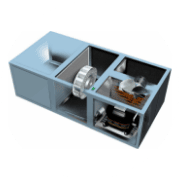

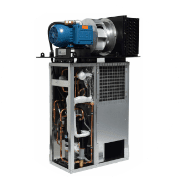

Floratech introduces the HEPAir system, an innovative new HVAC system. This environmental control system allows for the stable control of temperature, humidity, pressure, and cleanliness. It is designed to be used in cleanrooms as well as other settings such as pharmacies, labs, and hospitals.

Floratech through its newly formed subsidiary, Cleanroom Systems, Inc., purchases back portions of Clestra Cleanroom Technology Inc. from the French company, Clestra Hausermann. This acquisition further diversifies Floratech by adding a division dedicated to the design and manufacture of custom HVAC systems for the cleanroom and high-tech industries. Floratech also gains the building in which it currently resides as part of this acquisition.

Floratech secures a multi-year contract to supply the entire floral department of one of the largest U.S. supermarket chains.

Floratech introduces the HEPAir system, an innovative new HVAC system. This environmental control system allows for the stable control of temperature, humidity, pressure, and cleanliness. It is designed to be used in cleanrooms as well as other settings such as pharmacies, labs, and hospitals.

Floratech through its newly formed subsidiary, Cleanroom Systems, Inc., purchases back portions of Clestra Cleanroom Technology Inc. from the French company, Clestra Hausermann. This acquisition further diversifies Floratech by adding a division dedicated to the design and manufacture of custom HVAC systems for the cleanroom and high-tech industries. Floratech also gains the building in which it currently resides as part of this acquisition.

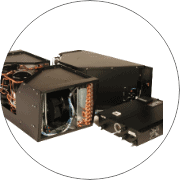

The company wins a major contract with one of the largest semiconductor lithography manufacturers in the world, supplying environmental control units (ECUs) to maintain precise temperature around the manufacturer’s system.

Floratech’s name is changed to Air Innovations. The rebranding of the company is done to help the company pursue a strategy of diversification. Air Innovations is focused on designing and manufacturing specialty and niche market HVAC systems for a broad array of industries.

Air Innovations wins its first significant contract with a supplier of scanners used to check luggage in airports, as required by TSA.

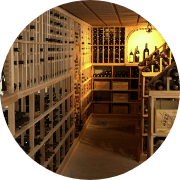

Air Innovations launches the Wine Guardian brand and commits to develop an array of products to meet the wide range of wine cellar cooling applications.

The company wins a major contract with one of the largest semiconductor lithography manufacturers in the world, supplying environmental control units (ECUs) to maintain precise temperature around the manufacturer’s system.

Floratech’s name is changed to Air Innovations. The rebranding of the company is done to help the company pursue a strategy of diversification. Air Innovations is focused on designing and manufacturing specialty and niche market HVAC systems for a broad array of industries.

Air Innovations wins its first significant contract with a supplier of scanners used to check luggage in airports, as required by TSA.

Air Innovations launches the Wine Guardian brand and commits to develop an array of products to meet the wide range of wine cellar cooling applications.

The company ships its 15,000th unit on May 12, 2010 (HEPAir System) and is named one of the fastest growing privately held companies in America by Inc. Magazine.

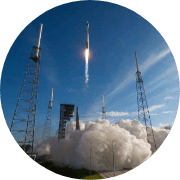

Air Innovations builds both a portable cooling unit that protects a rocket’s payload as it moves from the assembly facility to the launch pad at Wallops Space Center, VA and several cooling systems that regulate the interior of the rocket and create an ultra-dry state to support safe fueling prior to launch.

Air Innovations wins its first military contract to build an environmental control unit (ECU) to protect the computer that flies a military drone. This ECU is a “front line” tool transported on a Humvee. As a result, it needs to meet several challenging military specifications (Mil-spec), including the ability to survive (and operate!) after repeated drops from up to 4’ height and operation during blowing sand and rain.

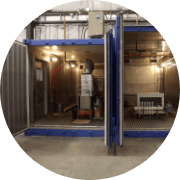

Air Innovations begins utilizing an in-house psychometric testing chamber. This chamber allows engineers to test products by simulating conditions in which those systems will actually operate, between 0°F and 120°F (-17°C and 48°C).

Air Innovations designs and manufactures environmental control systems for The Linq High Roller in Las Vegas, NV. At the time, this is the largest observation wheel in the world with 28 cabins holding 40 guests each. Redundant systems are installed under the floor of each cabin to maintain temperatures between 67 to 72°F.

Air Innovations launches Micro Environments (now called MyZone Systems). These personal climate control consoles are designed to provide heating and cooling to a user at a desk.

Air Innovations wins a contract to design and build explosion-proof environmental control systems to cool several variable frequency drives for a large centrifuge machine in the mining & drilling industry. These systems operate almost continuously in high-salt and high-dust conditions in temperatures anywhere between extreme cold (- 40°F) to extreme heat (+130°F).

Air Innovations designs and manufactures its largest cooling system after winning a contract with United Launch Alliance (ULA). Requiring 553-2,133 SCFM ±67 SCFM, this portable ECU is created to condition a rocket on its way to the launchpad.

The company develops its first international aerospace project after winning a project with the Korea Aerospace Research Institute (KARI).

The company ships its 15,000th unit on May 12, 2010 (HEPAir System) and is named one of the fastest growing privately held companies in America by Inc. Magazine.

Air Innovations builds both a portable cooling unit that protects a rocket’s payload as it moves from the assembly facility to the launch pad at Wallops Space Center, VA and several cooling systems that regulate the interior of the rocket and create an ultra-dry state to support safe fueling prior to launch.

Air Innovations wins its first military contract to build an environmental control unit (ECU) to protect the computer that flies a military drone. This ECU is a “front line” tool transported on a Humvee. As a result, it needs to meet several challenging military specifications (Mil-spec), including the ability to survive (and operate!) after repeated drops from up to 4’ height and operation during blowing sand and rain.

Air Innovations begins utilizing an in-house psychometric testing chamber. This chamber allows engineers to test products by simulating conditions in which those systems will actually operate, between 0°F and 120°F (-17°C and 48°C).

Air Innovations designs and manufactures environmental control systems for The Linq High Roller in Las Vegas, NV. At the time, this is the largest observation wheel in the world with 28 cabins holding 40 guests each. Redundant systems are installed under the floor of each cabin to maintain temperatures between 67 to 72°F.

Air Innovations launches Micro Environments (now called MyZone Systems). These personal climate control consoles are designed to provide heating and cooling to a user at a desk.

Air Innovations wins a contract to design and build explosion-proof environmental control systems to cool several variable frequency drives for a large centrifuge machine in the mining & drilling industry. These systems operate almost continuously in high-salt and high-dust conditions in temperatures anywhere between extreme cold (- 40°F) to extreme heat (+130°F).

Air Innovations designs and manufactures its largest cooling system after winning a contract with United Launch Alliance (ULA). Requiring 553-2,133 SCFM ±67 SCFM, this portable ECU is created to condition a rocket on its way to the launchpad.

The company develops its first international aerospace project after winning a project with the Korea Aerospace Research Institute (KARI).

Air Innovations sells its 50,000th unit, a DS025 wine cellar cooling unit from its Wine Guardian brand.

Air Innovations sells its 50,000th unit, a DS025 wine cellar cooling unit from its Wine Guardian brand.