For many industries, temperature control is essential to ensure that their critical processes operate efficiently and effectively. Pharmaceutical and semiconductor manufacturers need to ensure their environment is within a very precise temperature range as small fluctuations can have dramatic consequences on the quality of their sensitive products. Other industries may have critical equipment located in areas of the world that experience a broad range of extreme temperature conditions. They need to ensure that their equipment maintains consistent temperatures regardless of the ambient conditions.

Air Innovations specializes in broad and precise temperature control solutions for companies across numerous sectors. We integrate a variety of process controls — including temperature, filtration, air pressure, and humidity — into custom environmental control units (ECUs) built specifically for each customer’s unique applications.

Achieving the Optimal Temperature Range for Your Industrial Application

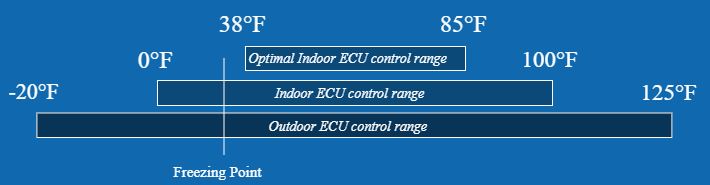

Our experienced in-house technicians are capable of distilling all environmental variables into the single best means of controlling the temperature of a designated space in your application. Air Innovations has designed environmental control systems that are able to maintain precise temperatures within +-0.02°. Other industrial temperature control systems we develop can maintain temperatures within a wide range of 0° F to 100° F (-18°C to 38°C), although precise temperature control within +-0.02° C is not typically employed within such a broad ambient spectrum.

Most indoor operating needs range between 38° F and 85° F (3° C and 29° C), which is often at odds with the fluctuating ambient (or outdoor) temperatures. We’ve successfully designed temperature control systems that maintain stable internal temperatures for applications where external temperatures range between -20° F and 125° F (-29° C and 52° C).

The Benefits of Temperature Control in Industry

Precise temperature control provides numerous benefits for manufacturers needing narrow limits on operational efficiencies and temperature requirements. Air Innovations’ precision temperature control technologies make our clients capable of the following:

- Maintaining product quality and site safety

- Improving process efficiencies

- Reducing operational costs, energy consumption, and maintenance needs

- Meeting government and industry standards

Examples of Broad vs. Precise Range Temperature Control for Industrial Applications

We’ve developed highly customized temperature control systems that meet the standards for the most technically demanding industries, including aerospace, military, pharmaceutical, healthcare, and semiconductor manufacturing.

In the following cases, our clients have depended on precise temperature control tolerances to ensure that the sensitive products they are manufacturing aren’t affected by extreme temperature changes: