Introduction

Aldevra had been selling refrigerators and temperature monitoring systems to federal agencies such as the Department of Veteran Affairs (VA) and the Department of Defense for years, when customers presented a new challenge. Through Aldevra’s strong ties with these government agencies, they became aware of a need for a portable, enclosed solution to store sterile supplies and equipment that was sophisticated enough to meet stringent VA and Joint Commission requirements. The company didn’t yet sell such a system, so they started researching options.

An Unexpected Collaboration

Aldevra discovered a public bid notice site and learned that another VA employee was already working with a local, small business manufacturer to develop a prototype for a sterile storage cabinet. The manufacturer’s representative, Dynamic Product Solutions, invited Aldevra to join their team of qualified sales agents to help get the best solution out to VA hospitals and other facilities.

Air Innovations was chosen to redesign and manufacture the sterile storage cabinet based upon their production capabilities and engineering expertise, which would enable them to take the current design to the next level.

The varied expertise of Air Innovations, Aldevra, and Dynamic Product Solutions made it possible for the trio to design and manufacture a sterile storage cabinet that could precisely control temperature, humidity, pressure, and cleanliness to meet any industry standards.

“Aldevra’s longstanding connection to VA hospitals played an instrumental role in our partnership, as did the vast HVAC knowledge Dynamic Product Solutions sales engineers had,” said Mike Wetzel, President and CEO of Air Innovations. “This depth of experience combined with our decades spent creating pristine environmental conditions enabled our partnership to tackle the redesign.”

The Challenges

Up untilthis time, keeping a VA hospital equipped with sterile surgical instruments was an inefficient, labor-intensive process. In some cases, staff would have to walk to a faraway temperature-controlled room where medical instruments and supplies were housed. Or, they had to wait for the items to be delivered by a Sterile Process Services team. Staff would drive to a hospital to collect all of their surgical instruments and bring them back to a facility to sterilize each instrument before returning them. If an item went unused within 72 hours, it had to be returned to be cleaned again. This process was repeated every three days.

In addition, many facilities struggled to control an area’s temperature and humidity, especially in older locations and leased spaces. Some customers needed an affordable response to a regulatory citation for storing items in properly controlled environments, as budgets wouldn’t allow for building new cleanrooms or renovating HVAC systems, while others needed a temporary solution during hospital construction and renovation.

“It’s a powerful moment when we can listen to our customers’ needs, note their suggestions, connect directly with engineers, and circle back to show the customer how and where their feedback was incorporated in the redesign of the sterile storage cabinet. It was a unique, awesome experience and demonstrates the benefit and value of working with U.S. small businesses.”

Maggie Bullard-Marshall, Vice President at Aldevra

The Solution

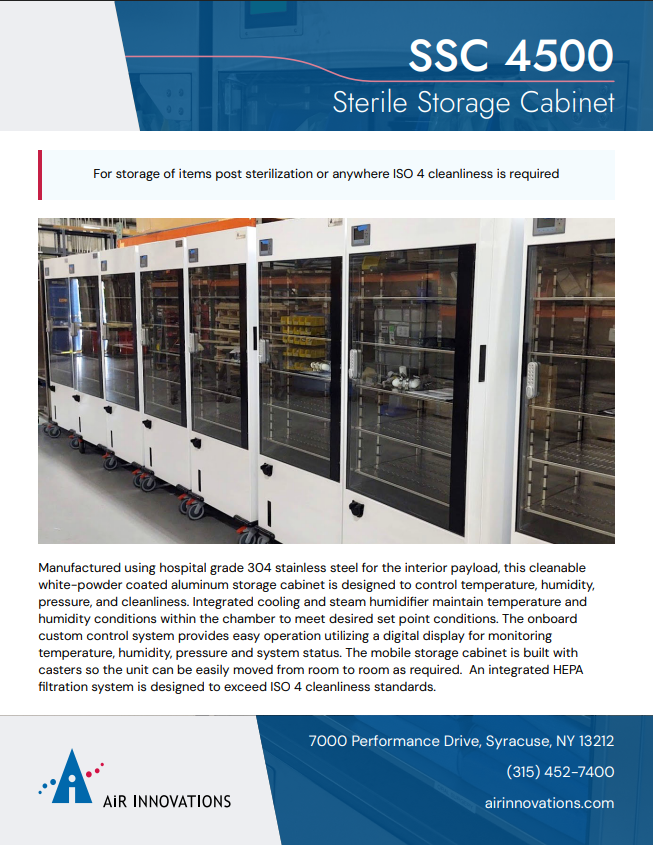

Air Innovations sterile storage cabinets were designed to replicate cleanroom conditions. Temperature, humidity, pressure, and cleanliness are controlled with precision to prevent decay and to preserve the shelf life of medications, surgical instrumentation, and other stored medical goods. VA hospitals outfitted with these units are able to meet compliance regulations with confidence.

In addition, each unit is equipped with HEPA filtration, which creates a barrier between sterile medical items and any number of contaminants such as dust, bacteria, and viruses. As a result, the sterile storage cabinets exceed ISO 4 Cleanliness standards.

The units also feature a powder-coated, aluminum exterior and stainless-steel interior that is hospital grade and easy to clean. The cabinets are fitted with bottom casters and handles on the sides, making them portable, thus allowing VA staff to move the units from room to room as needed. And a digital display enhances ease of use so that truly any medical professional can operate the system.

“Being able to collaborate with Mike Wetzel and his team at Air Innovations on the features of the redesign was energizing,” said Mike DeGaetano, Sales Director, Dynamic Product Solutions. “The engineers at Air Innovations really listened to our customers and ended up coming back with a product that exceeded all of our expectations. It’s a win-win for everyone.”

Minimal Disruption To Patient Care

The team utilized basic refrigeration components and functionality—compressor, condenser, expansion valve, and evaporator—to measure and control temperature, humidity, and pressure. Since the units would be used in hospital settings where time is of the essence, Air Innovations designed the refrigeration system, sensors, and controls into a cassette so it could be easily removed and replaced within 30 minutes. Once the new cassette is in place, the previous one can be repaired on-site or off-site causing minimal disruption to patient care.

Humidity Contained

The sterile storage cabinets were also engineered to control humidity across ambient conditions. The most effective way to control humidity is to set the temperature coming off the cooling coil to a dew point of 52℉. At this temperature, it becomes easier to keep the relative humidity under 60%. Moisture can be removed or added back depending upon the ambient air conditions. For instance, during winter some arid climates may require water to be added to the front of the cabinet via a built-in humidifier, whereas moisture needs to be removed from a discard pan under the unit during humid spells.

Positive Pressure

Given the sensitive nature of the items inside the cabinet, another design requirement was creating positive pressure. Positive pressure means the pressure is higher inside the cabinet than outside. As a result, contaminants and humidity cannot enter the space. Since the cassette is removable, the cabinet is not perfectly sealed. This was engineered to discharge very clean air versus drawing in humidity and airborne particles that originate in the room the cabinet is stationed in.

Today, Aldevra’s VA hospital clients have eliminated the need for Sterile Process Services to clean and transport surgical instruments every three days. Now, they simply sterilize the items and stock the sterile storage cabinets on an as-needed basis. These facilities have been able to save resources while maintaining the highest level of safety for their healthcare community.

“I credit the VA staff for being so forward-thinking in their search to find a cutting-edge solution,” added Bullard-Marshall. “We are all thrilled with the end result.”