Similar to all medical facilities, hospitals are subject to strict hygiene standards. These requirements and restrictions are aimed toward ensuring the health and well-being of all patients, facility employees, and visitors. They may include implementing rigorous cleaning schedules as well as integrating specialized equipment—e.g., HVAC systems—to reduce the risk of contaminants spreading from room to room and patient to patient.

When employed properly, HVAC equipment can minimize the transmission of contaminant-laden air, which, if left unchecked, can infect those who come into contact with it. For this reason, high-performance HVAC units are often used in hospitals to prevent the ingress or egress of hazardous compounds.

Below we provide an overview of the importance of HVAC systems in hospital infection and contamination control applications.

An Introduction to Hospital Contamination and Infection Control

Medical facilities are regularly at the front lines of emergencies, and it’s crucial that they maintain the equipment necessary to react quickly in the case of novel infections. HVAC systems are a critical line of defense against the spread of contagious diseases.

The COVID-19 pandemic has underscored the importance of having contamination control measures at the ready. Although the novel coronavirus is primarily transmitted through large droplets—such as those produced by coughs and sneezes—there is also evidence that it may be transmitted through fine airborne particles. In light of this information, hospitals nationwide have been forced to assess their contamination containment strategies to slow the spread.

As former FDA commissioner Dr. Scott Gottlieb has pointed out, “The COVID-19 pandemic has exposed serious gaps in our nation’s pandemic preparedness… [and it] will not be the last public-health emergency to threaten American society.” For this reason, it is essential to invest in the “scientific, public health, and medical infrastructure needed to prevent, detect, and respond to the next infectious disease threat”, which, for hospitals, includes HVAC systems.

The Importance of HVAC Systems in Hospital Infection Control

HVAC systems are designed and constructed to regulate airflow, allowing facilities to maintain the temperatures that are ideal for both human comfort and medical equipment functioning. In medical facilities, HVAC systems are also used to prevent the spread of viruses and bacteria. When used in such applications, they generally incorporate specialized components, such as:

High-efficiency particulate air (HEPA) filters to remove airborne contaminants as small as .3 microns Built-in, wall-mounted heating and cooling units to optimize ceiling and floor space Static cooling systems to cool—but not circulate—the ambient air Multiplex air jet outlet systems to distribute air to specific areas of a room.

Uses of HVAC Systems in Medical Environments

HVAC systems serve numerous functions in medical facilities, including, but not limited to, the regulation of airflow and temperature. Here are some common applications:

Cleanrooms

Cleanrooms provide an enclosed and controlled environment for medical operations. They are available in two main designs:

- Positive pressure cleanrooms are pressurized to higher levels than the surrounding rooms. If the room seal is broken, the pressure differential forces the internal air outward, preventing contaminants from entering. They are used for the protection of patients that are immunocompromised or otherwise vulnerable to infection.

- Negative pressure cleanrooms are designed to have lower pressure levels than the surrounding rooms. If the room seal is broken, the pressure differential forces external air inward, preventing contaminants from escaping. They are used to isolate patients with highly contagious diseases (e.g., COVID-19), so others are not infected.

Cleanroom Design and Construction Guidelines

Both positive pressure and negative pressure cleanrooms find application in hospitals. When designing and constructing either of them, it is important to meet the following guidelines:

- Create a positive or negative pressure environment, as needed

- Close out the room vents to guarantee the room is totally enclosed

- Install an HVAC heating/cooling system to ensure patients and medical practitioners are comfortable

- Add a MERV17 medical-grade HEPA filtration unit to remove dust and particulates

- Integrate a UV light unit to sterilize any remaining particles and inactivate bacteria and viruses

Sterile Storage Cabinets

Sterile storage cabinets are used to ensure the sterility of equipment rather than the safety of patients and staff members. These cost-effective cabinets maintain cleanroom conditions for sterilized equipment, but their portability allows them to be positioned conveniently wherever needed in the hospital. Sterile storage units do not just create a barrier between items and potential contaminants like dust, dirt, viruses, or bacteria. They regulate the temperature and humidity to prevent decay and increase the shelf life of stored goods.

Hospital Environmental Control Solutions From Air Innovations

For over three decades, Air Innovations has specialized in designing, testing, and manufacturing custom environmental control solutions. We offer a wide range of products designed for use in the healthcare industry, including these:

IsolationAir® System for Hospital Contamination Control

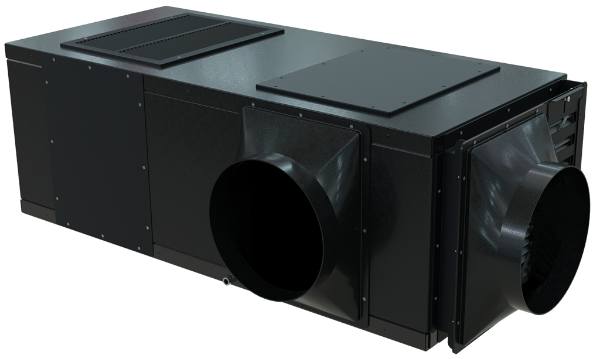

IsolationAir® unit is a portable contamination control system with built-in medical-grade HEPA filtration, UV sterilization, air conditioning, and ductwork.

It can be moved throughout a facility to transform standard rooms into positive-pressure or negative-pressure isolation environments for patient care or containment purposes.

Note: The IsolationAir unit is an air filtration device and does not sterilize or disinfect a room or any of its contents. It is not a medical device and makes no claims for patient or healthcare outcomes. It is not intended for use in the diagnosis of disease or other conditions or in the cure, mitigation, treatment, or prevention, of disease in humans or in other animals.

Sterile Storage Cabinets for Sterile Instrument Storage

The SSC4500 storage cabinet provides a contained, cleanroom environment with full temperature and humidity-control capabilities. Due to its HEPA filtration unit and medical-grade steel construction, it offers all the features necessary to maintain sterile instruments without the need for a full-sized cleanroom.

Some common applications for the SSC4500 include hospitals, life sciences research, precision manufacturing, and retrofitting medical facilities with additional storage.

Note: The SSC4500 is not intended for use in the diagnosis of disease or other conditions or in the cure, mitigation, treatment, or prevention, of disease in humans or in other animals.

Nimbus + Microburst System for Whole-Room Disinfection

Nimbus® by Nevoa was developed through a partnership between Air Innovations and Nevoa. The whole-room disinfection system quickly introduces and removes a pathogen-eliminating solution through atomization and dehumidification and air scrubbing, respectively. This process ensures the room is fully disinfected without relying on manual cleaning operations.

Air Innovations does not represent Nevoa, nor sell its Nimbus device. We manufacture a critical component (the dehumidifier) that goes into the Nimbus unit and is only shown here to illustrate the OEM capabilities of Air Innovations.

Air Conditioners for Cleanrooms

Air Innovations features an entire division dedicated to unitary and custom HVAC systems designed for use in cleanrooms and other critical environments. Our clean room air conditioning systems can be tailored to your exact specifications in size, features and functionality. Our product offerings include standard and custom cleanroom equipment:

ArrayAir: for smaller cleanrooms

HEPAir: for greater versatility

AdvancAir: for broader customizability

Why Choose Air Innovations?

At Air Innovations, we have extensive experience designing and building custom environmental process control systems for unique applications. Equipped with over three decades of industry experience, our team has the knowledge and skills to ensure every system we deliver offers the control over temperature, humidity, filtration, pressurization, and other environmental factors needed to meet customer requirements. To learn more about our HVAC solutions and how they benefit the healthcare industry, contact us today.

Download Infographic