At Air Innovations, we specialize in designing, developing, and constructing specialty environmental process control systems for precision temperature, humidity, and filtration control. Environmental control units (ECUs) are devices used to regulate conditions within a space in various industrial applications. Our solutions ensure customers achieve optimal process efficiency and comply with industry standards and government regulations.

What differentiates Air Innovations is our depth of experience in understanding our clients’ technical requirements, parameters, and goals and designing highly specialized environmental process control systems that meet their unique needs. We specialize in solutions that cannot be addressed by standard HVAC equipment.

CUSTOM CLIMATE CONTROL

Custom solutions enable industry professionals to depend upon ECUs to meet their unique specifications, including operating environment, size constraints, regulatory and industry standards, and efficiency requirements. Most often, our environmental control units regulate these aspects:

Temperature – Control broad temperature ranges from 0°F to 100°F (-18°C to 38°C) with tolerances as precise as ±0.02°C

Humidity and Dew Point – Control tolerances to ±0.5% RH; Desiccant to 95% RH

Filtration – HEPA, ULPA, and molecular

Our custom ECUs can be configured to match the application and space constraints of your project:

- Integrated – Integrated units accommodate existing equipment structures, resulting in a smaller footprint, greater system efficiency, and lower installation costs.

- Mounted – Mounted units are attached to existing systems and can reduce a system’s overall weight and footprint.

- Standalone – Standalone units are placed around equipment rather than in or on them, allowing for greater flexibility regarding system location, installation, configuration, and performance capabilities.

Our systems can also be customized to be explosion-proof for applications involving combustible substances or flammable compounds, such as dust, metal shavings, and other airborne particles. These ECUs have been designed to mitigate the risk of ignition and explosion in aerospace, military, oil and gas, milling, and pharmaceutical and medical industries.

Our team has the depth of experience to design and deliver enduring solutions to even the most unique requirements.

HOW WE CREATE CUSTOM ENVIRONMENTAL CONTROL SOLUTIONS

Since environmental control requirements vary widely depending on industries, companies, and processes, there is no one-size-fits-all solution for controlling temperature, humidity, cleanliness, and pressure. Our highly experienced, multi-disciplined engineering team collaborates with business and technical leaders on project scoping, concept designs, prototyping, and in- and out-of-house testing. By offering complete custom solutions, we ensure the systems we deliver fully comply with the requirements and restrictions of any application. Air Innovations facilities manufacture small runs and mass-produced custom ECUs for OEMs.

ENVIRONMENTAL CONTROL PRODUCTS

In addition to designing and building custom solutions, Air Innovations has a suite of standardized environmental control systems that are applicable across industries. From cleanroom ECUs to systems designed to keep individuals comfortable and safe in various environments, our products are held to the same rigorous standards and industry regulations as our custom solutions.

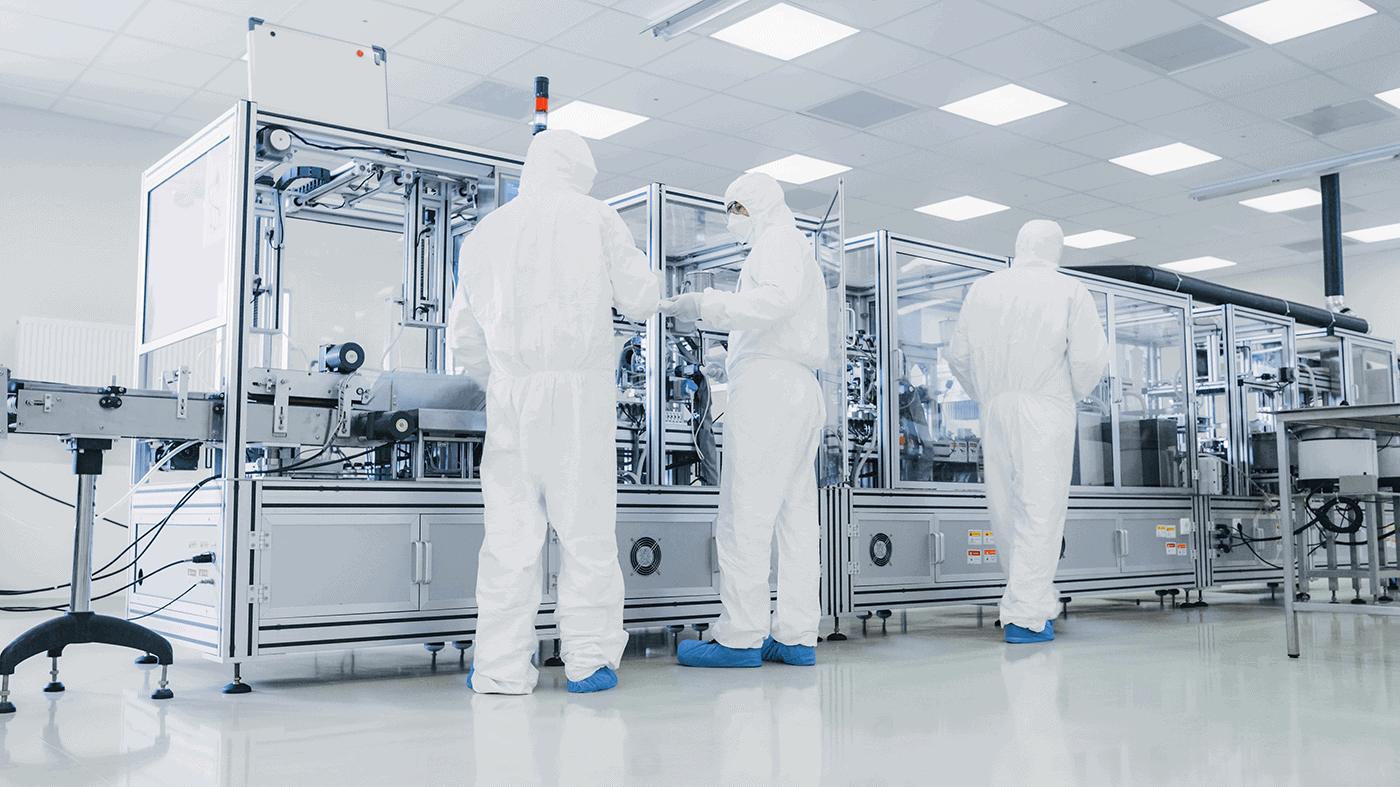

CLEANROOM SYSTEMS

Air Innovations cleanroom environmental control systems deliver real-time monitoring and controlling of temperature, contaminants, humidity, air pressure, and airflow rate to meet stringent process requirements. They operate independently of a building’s central HVAC system and were designed for one-through or recirculating applications. The cleanroom systems can also control positive or negative pressure. One of the most critical aspects of cleanroom HVAC systems is air filtration. Our ECUs use HEPA filters to maintain ISO 14644 standards and filter out at least 99.97% of all airborne particulates 0.3 microns or larger.

ENVIRONMENTAL CONTROL SYSTEMS FOR THE HEALTHCARE INDUSTRY

Air Innovations understands the challenges of keeping employees and patients safe in a healthcare environment. We offer multiple standardized solutions to help maintain hospital environments. Our Sterile Storage Cabinet is a deployable solution that keeps surgical instruments sterile post-autoclave. IsolationAir® systems utilize medical-grade HEPA filtration, UVC sterilization, and air conditioning to transform standard patient rooms into negative or positive pressure environments. Lastly, the HEPAiRx system is a window-mounted air purifier that filters and reduces indoor pollutants through HEPA filtration. Air Innovations can also develop custom environmental control systems for healthcare applications.

MYZONE DESK CONSOLE MANAGEMENT SYSTEM

Air Innovations designed a desk console management system that combines environmental control (heating and cooling), lighting control, and integrated desk-leg lift control functions to ensure a comfortable and personalized workspace. The MyZone® system is simple to install, compatible with most standing or sitting desks, and controlled through a non-fixed touchscreen remote.

WINE GUARDIAN LOW-TEMPERATURE HVAC SYSTEMS

Wine Guardian, an Air Innovations brand, provides specialty HVAC systems that control the temperature and humidity of wine cellars for the long-term storage of wine. Our wide variety of low-temperature HVAC systems is also well suited to fur storage, art and document preservation, food storage, humidor rooms, and computer system rooms. Like all Air Innovations products, Wine Guardian wine cellar cooling units can also be customized to accommodate unique requirements in any size application.

PERSONAL FORKLIFT AIR CONDITIONER

Forklift and industrial equipment operators are routinely exposed to extreme heat and humidity in factories and warehouses. Air Innovations designed the Cabin Cool System to keep drivers safe and productive. The compact unit blows cool air directly onto vehicle operators in an open cabin environment, keeping their line of sight undisturbed. This system can be mounted to any new or used industrial vehicle, allowing users to retrofit their existing vehicles rather than purchasing more expensive solutions.

What excites the Air Innovations team is creating, testing, and deploying custom environmental control systems to help our clients solve problems and achieve goals. We maintain a dedicated in-house research and development department to conduct data and performance validations. We also understand specialized requirements and limitations better than anyone and have a track record of exceeding our client’s expectations through innovative, durable solutions. All Air Innovations products can be certified to any of the following safety and performance standards: ETL, CSA, CE, CCC, ANSI, UL, SEMI, and MIL-STD. Contact us today for more information on how Air Innovations can help protect your products, processes, and people.

OTHER CONSIDERATIONS WHEN DESIGNING SYSTEMS INCLUDE:

- Cost

- Space and size constraints

- Indoor/outdoor

- Pressurization

- Configuration: Integration into an existing system, standalone, or mounting

- Volumetric airflow: How much air they need to pass through the system in a period of time, typically in cubic feet per minute (CFM)

- Once-through air or recirculation of air: Air can be much cleaner if it’s recirculated through a captive space

- Redundancy: How critical is it for the system never to go down?

- Exposure: To chemicals, weather, transportation, military settings, explosion-proofing, and/or seismicity

- Variation of the heat load: A system might need to go down to -2° C (29°F) in January, but hits 106°F or higher in July. The system had to be designed to deal with those extremes.

- Environmental friendliness/certifications: The global warming/environmental impact potential of the refrigerant used within the system

- Electrical characteristics: 50Hz/60Hz or other; systems on a ship or plane may have different characteristics

- Construction materials: Material factors for system construction are usually dependent on the factors above.

- Temperature control: Control environments from 0°F to 100°F (or -18°C to 38°C) with tolerances as precise as ±0.02°C

ECUs for Specialized Applications

We supply environmental control and HVAC systems to customers in a wide range of industries including, but not limited to, the following:

| Aerospace. In the aerospace industry, system failure can result in catastrophic consequences. Our environmental control units offer reliable performance, whether they are used during pre-launch payload cooling or instrument calibration operations. |

| Healthcare. In the healthcare industry, facilities must abide by strict sanitation standards to ensure the health of patients, personnel, and visitors. We offer environmental control solutions that help preserve hygienic conditions by preventing pathogen transmission, maintaining instrument sterility , isolating quarantine areas, and sterilizing spaces . |

| Military. Military equipment is often subjected to harsh conditions. Our ECUs are designed and built for durability and reliability, ensuring they continue to offer temperature, humidity, and other environmental condition control even when used in some of the most challenging environments. |

| Pharmaceutical. Similar to the healthcare industry, the pharmaceutical industry is subject to stringent standards to ensure the health and wellness of consumers. Our environmental control units offer precise control over environmental conditions, which can lead to better process and product quality. |

| Semiconductor. During semiconductor manufacturing operations, temperature and humidity can significantly affect the quality of the final product. Our ECUs allow manufacturers to control conditions within the manufacturing facility closely and carefully to minimize the risk of product damage or contamination. |

Why Partner With Air Innovations?

At Air Innovations, we are an industry leader in the design and manufacture of custom environmental control solutions. Equipped with extensive industry-specific experience (including for the aerospace, healthcare, military, pharmaceutical, and semiconductor industries), we can provide an appropriate ECU for virtually any environmental control need.

To learn more about our environmental control solutions or discuss your application requirements with one of our experts, contact us today.

Read more detailed information on our expertise and capabilities at the links below. To see what we have done in a specific industry, see our Industries section. Or browse our Case Studies.