Air Innovations has dedicated an entire division to designing and manufacturing unitary and custom HVAC systems for cleanrooms and critical environments.

Cleanroom environmental control units (ECUs) maintain pristine conditions, so workers and machines operate productively and contamination-free. Our products are the only fully integrated modular environmental systems created for the cleanroom industry.

As with all Air Innovations ECUs, our cleanroom air conditioning systems can be tailored to your size, features, and functionality specifications.

HOW OUR CLEANROOM SYSTEMS WORK

Cleanroom environmental control systems maintain temperature, humidity, sterility, air pressure, and flow rate according to the requirements of an application.

TEMPERATURE AND HUMIDITY CONTROL

Temperature gradients and moisture can compromise the operation of sensitive electro-optical components and result in contamination. Our cleanroom ECUs control both temperature and humidity since temperature determines the percentage of relative humidity (RH) at a given atmospheric pressure.

PARTICULATE CONTROL

One of the most critical aspects of cleanroom HVAC systems is air filtration. Airborne particles such as mold, pollen, and dust can jeopardize the integrity of critical manufactured components, such as sensitive electro-optical parts. Air Innovations ECUs maintain ISO 14644 standards. In addition, cleanroom HVAC systems usually incorporate high-efficiency particulate (HEPA) filters, which are necessary for applications that rely on sterility, including research laboratories, medical facilities and pharmaceutical manufacturing and testing operations.

Our HEPA filters can separate at least 99.97% of all airborne particulates 0.3 microns or larger. Ultra-low particulate air (ULPA) filters can remove 99.9997% of particles 0.12 microns or larger.

Lastly, Air Innovations’ environmental control units use microbial control to prevent airborne mold or bacteria from contaminating sensitive pharmaceutical, medical, or other products. Ultraviolet germicidal irradiation (UVGI) is integrated into the air filtration system to kill microbes effectively.

AIR PRESSURE AND FLOW RATE CONTROL

ECUs maintain clean air and optimal temperature and humidity by changing or passing air within the cleanroom multiple times per hour. Depending on the specifics of an application, they can keep higher (positive) or lower (negative) air pressure inside the cleanroom.

STANDARD AND CUSTOM CLEANROOM HVAC SYSTEMS

Air Innovations has solutions for almost any environmental cleanroom challenge, from small cleanroom environments to more extensive projects requiring versatility.

For glovebox-sized cleanroom applications, Air Innovations has developed the ArrayAir system. These systems are portable and lightweight HVAC systems designed to fit inside small enclosures up to 30 cubic feet. These systems have quiet operation and can cool and heat 5ºF below/above room temperature.

Designed for larger and more advanced cleanrooms, the HEPAir system is a self-contained 2-in-1 unit engineered to match most existing fan/filter units. This makes it an excellent “do-it-yourself” solution. HEPAir systems are optimal in softwall, single-pass air cleanroom. They can also control positive and negative pressure.

Our cleanroom HVAC systems can accomplish the following:

Eliminate open-drive or belt-driven parts that could generate particles and contaminate the air stream

DX, chilled water, or thermoelectric cooling

Explosion-proof capabilities

Up to 5,000 CFM

We also produce temperature and humidity-controlled cabinets that create cleanroom-like conditions for the storage of sterilized equipment. These sterile storage cabinets (SSC 4500) are compact and deployable making them a great solution when constraints make it impossible to construct an entire cleanroom.

-

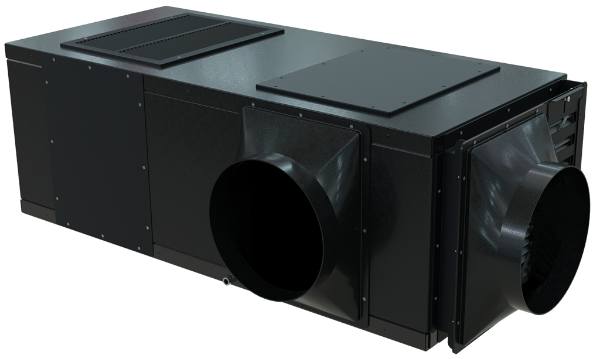

Standard HEPAir System

Click below to learn more

Diverse Applications Independent Operation Modular Humidity Management Integrated High Efficiency Filtration< Previous Next > -

Custom AdvancAir Unit

*Example of a custom HVAC unit. Visual components and features will vary depending on your specific application.

Click below to learn more

< Previous Next >

Cleanroom Planning Guide

Learn more about developing a cleanroom environment with our “Cleanroom Planning Guide” eBook

CUSTOM CLEANROOM

ENVIRONMENTAL CONTROL UNITS

Our industry-specific expertise allows us to provide ECUs suitable for any environmental control need. Customizability gives our clients the tools to keep their cleanrooms compliant with performance requirements and industry regulations regardless of size or environmental constraints.

AdvancAir systems provide complete customization that standard environmental control units cannot offer. Here are just a few of the unique specifications we can accommodate:

Tight temperature control as low as ±0.02°C

Chilled water or DX-based systems

Humidification control to ±0.5% RH

Computer-managed, system-wide control

Why We’re The Cleanroom Experts

Cleanroom Systems is a division of Air Innovations, which has over 25 years of experience designing, testing, and manufacturing environmental process control systems for various applications. Equipment is produced in a 40,000-square-foot, facility in Syracuse, New York.

We maintain a dedicated R&D department to test and validate our engineered solutions. Our multi-disciplined engineering team has experience designing electrical controls, refrigeration, piping, air flow, filtration, cabinetry, and enclosures. Our products can be certified to the safety and performance standards of ETL, UL, CSA, CE, ANSI, SEMI or MIL-STD.

AirArray

- Portable and lightweight

- Fits enclosures up to 30 cubic feet in size

- Quiet Operation

- Cools and heats 5ºF below/above room temperature

HEPAir

- Self-contained 2-in-1 unit

- Designed to match to most existing fan/filter units

- Excellent “do-it-yourself” solution saves time and money

- Best in softwall, single-pass air cleanrooms

AdvancAir

- Tight temperature control as low as ±0.02°C

- Humidification control to ±0.5% RH

- Chilled water or DX-based systems

- Computer-managed, system-wide control

UNMATCHED EXPERTISE: AIR INNOVATIONS DELIVERS CUSTOM ECUS THAT MEET YOUR NEEDS

Environmental control units are crucial components for cleanrooms, ensuring they maintain optimal environments suitable for stringent manufacturing or production needs. Regardless of the cleanroom ECU you need, Air Innovations can provide a solution with the level of customization you require.

Air Innovations is the only provider of fully integrated, modular environmental control systems for cleanrooms. We can customize ECUs to meet all kinds of cleanroom specifications across various industries.

Download our whitepaper to learn more about cleanroom technology, or contact us for more information about our products. If you’re ready to start your solution, request a quote today.

Let's Get in Touch

For info on tabletop humidifiers labeled “Air Innovations”

QVC, The Home Depot, and other retailers sell some consumer products, like tabletop humidifiers, labeled “Air Innovations” that are not affiliated with our company, Air Innovations LLC. We sell environmental control equipment for businesses. Please contact the manufacturer’s customer service at 1-844-600-1370 with any questions about your product.

For info on tabletop humidifiers labeled “Air Innovations”

QVC, The Home Depot, and other retailers sell some consumer products, like tabletop humidifiers, labeled “Air Innovations” that are not affiliated with our company, Air Innovations LLC. We sell environmental control equipment for businesses. Please contact the manufacturer’s customer service at 1-844-600-1370 with any questions about your product.