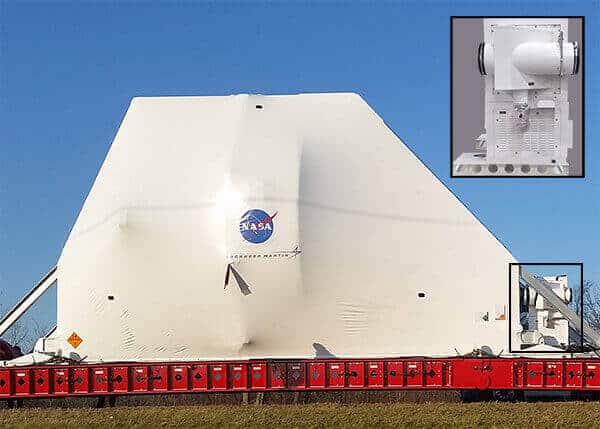

Lockheed Martin, leader in space innovation, asked Air Innovations to customize an aerospace environmental control unit (ECU) to support the Orion program’s space capsule while earth-side. The system would need to protect the capsule during transportation on the ground, as well as in the air aboard a Super Guppy, until the unit was connected to the rocket. It would also need to maintain the environment within the capsule after re-entry and landing.

The Challenge

The challenge was countering significant fluctuations in temperature and pressure that could jeopardize the Orion capsule’s highly sensitive electronics. The system would need to tolerate ambient temperatures up to 120℉, with a max dewpoint of 96℉—the latter alone requiring 10,000 BTUs/h.

In addition to the challenges of exposure to extreme environments, the design parameters presented strict weight restrictions for transporting the capsule and the Air Innovations ECU. The solution provided by Air Innovations would have to abide by strict weight limits and not exceed 800 pounds. Our engineers would also need to find a way to combat condensate associated with changes in temperature and pressure aboard an airplane.

Lastly, given the incredibly valuable nature of the space program technology, the system devised by Air Innovations would have to be highly adaptable to every possible scenario, including power outages and system failures more common on airplanes and sea vessels.

The Solution

Air Innovations designed, tested and manufactured a specialized environmental control unit—with its own redundancy built in—configured to provide recirculated air control to the CSM cover. To further guard against power or system failure, the unit utilized a custom power converter to change 60Hz to 400Hz frequency when being transported from the ground to the airplane or ship. In addition, the unit was equipped with an input current and voltage meter to ensure the power quality.

A key initial step was to perform extensive heat load calculations, which were complex due to exposure to extreme environments. In addition, Air Innovations defined the test protocol for Lockheed Martin.

To function while inside the Super Guppy on the ground and in flight, make-up air was used to pressurize the capsule and was drawn into the ECU from the ambient air. The evaporator coil was set to a temperature ideal for humidity control and to achieve maximum cooling requirements. Then, the air was passed over an electric heater for precise temperature control. Finally, the system was engineered to pass air through a HEPA filter before being delivered to the capsule.

The painted aluminum unit was configured at 1,350 CFM capacity, delivered at 0.5” wc static pressure. The unit also featured E-coated evaporator and condenser coils to prevent corrosion from salt air. In addition, an integral tank was installed to collect and drain condensate while in flight.

The aerospace environmental control unit was designed to control the temperature between 63-81℉ with less than 60% relative humidity at all times. The finished product also included hot-gas bypass refrigeration control and a 12.5KW electric re-heater.

The Result:

An environmental control system that included the following:

- Cooling, heating, dehumidification, pre-filtration and HEPA filtration

- A 60Hz to 400Hz frequency power converter

- The unit measured 26” X 60” X 56”

- Design output conditions of 63°F -81°F ±2°F with less than 60% RH

- Maximum dewpoint of 96°F

- 1,350 CFM fixed airflow capacity

- 5” external static pressure

- Separate auto-tuning PID loop controllers for temperature and read-only for humidity

- ISO class 8 to 99.97% @ 0.3µ HEPA

- E-coated evaporator and condenser coils

- Integral air-cooled condenser with nominal 2.5 ton scroll compressor

- Hot-gas bypass refrigeration control

- 5kW electric re-heater

- Meets all UL certification requirements

If you’re ready for a custom solution from Air Innovations, like this custom pharmaceutical environmental control unit, contact us by submitting a Project Inquiry or by calling 1-800-835-3268 today.

If you would like to see case studies for other industries, view our general case studies page. If you are interested in seeing more case studies for the semiconductor industry, look at the items below. We also have whitepapers available covering the aerospace industry, the semiconductor industry, and our Micro Environments product line. The whitepaper page can be found here.