Tag: Cleanroom

Standard HVAC systems control humidity, temperature, and air pressure. They can also provide filtration and control the speed and direction of airflow into and out of a space. Cleanroom HVAC systems, however, have higher air exchange rates and are equipped with high-efficiency particulate (HEPA) filters to maintain a sterile environment. This allows them to meet stringent air filtration standards for industries like medical, pharmaceutical, and research & development laboratories. Selecting the right cleanroom HVAC system to meet your needs will depend on multiple factors that influence the size and design of your system.

What People Overlook When Looking for a Cleanroom HVAC Unit

There are several qualities buyers tend to overlook when selecting a cleanroom HVAC unit for their specific space and application. Typically, a buyer knows the size of the room and the cleanliness level they require, but this is only a fraction of the information manufacturers need to make or select your cleanroom’s HVAC unit. For example, you may know you need an HVAC cleanroom system for a 20’ x 20’ ISO Class 8 cleanroom, but you may not be aware of the room’s heat load or temperature range. It’s ideal to identify the following information before you proceed with the HVAC system design process.

Knowing the Total Heat Load in the Room

Understanding the total heat load of the room is crucial because it identifies the amount of heat that the cleanroom HVAC system will need to remove. Every device in that room that is drawing power must be considered as part of the total heat load. The HVAC unit you choose should be capable of removing that amount of heat via the air conditioner. To build a system of sufficient size to handle your heat load, determine the number of kilowatts each piece of equipment in your cleanroom produces. However, you should also include these factors in your calculations:

- Square footage of your cleanroom

- Number of people working in the space

- Number of lights and their type (fluorescent or LED)

- Number of windows in the room, as well as how much light they let in

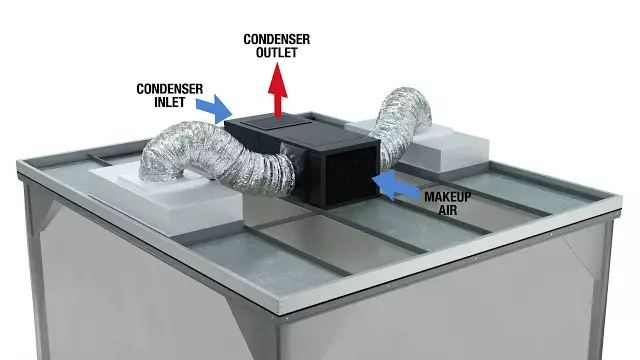

Where’s Air Coming From – Inside vs. Outside Air

Understanding where your HVAC system draws its air from is critical for effective cleanroom cooling. Air can come from outside the facility or from an indoor location around the cleanroom. You need to determine the origin of the air to ensure it’s in an acceptable condition before the system pressurizes it. It’s also vital to know the air change rate and if your cleanroom system recirculates the air or is a single-pass system. The air change rate is how often external filtered air replaces the air currently in the cleanroom. A recirculating cleanroom system filters and recycles the air, while a single-pass system exhausts the air outside the cleanroom.

Existence of Exhaust in the Cleanroom

While important, many buyers never think about exhaust. All the air that the system exhausts from the room needs to be made up with what is essentially “more expensive” air. This is to say that, unlike recirculated air from within the cleanroom, incoming ambient air requires treating, consuming more energy and utilizing additional equipment to process. Recirculated air is stable as it’s already conditioned, with small amounts of heat and moisture added. Knowing the amount of air a cleanroom exhausts — as well as how much it leaks — is crucial to selecting the right-sized system to meet your temperature and humidity requirements.

What’s the Temperature, Relative Humidity, and Dew Point Range

Knowing your cleanroom’s ranges for temperature, relative humidity, and dew point throughout the year is essential when designing your HVAC system. Each value can change drastically throughout the different seasons. However, identifying your humidity at any given time, for example, is not enough. You must also know the temperature in the room at that particular humidity level, or vice versa. Pinpointing the maximum humidity at the highest temperature and the maximum humidity at the lowest temperature each season will help you to determine the appropriate type and size of HVAC system for your cleanroom.

Cleanroom HVAC Solutions From Air Innovations

When trying to identify the optimal cleanroom HVAC design for your operation, first gain a comprehensive understanding of your cleanroom’s conditions to select the right unit and size for your space. Air Innovations is an industry leader in designing, manufacturing, and testing custom environmental control systems when standard HVAC equipment won’t do the job. Since 1986, we’ve helped clients in diverse industries manage temperature, humidity, pressurization, and filtration in their process control systems.

As part of our areas of expertise, we deliver high-performance HVAC solutions for critical environments like cleanrooms. Our product line includes standard HVAC systems like our HEPAir cleanroom unit or more customized solutions.

Contact us today with questions on our systems or to begin your cleanroom HVAC unit design and build.