Tag: Aerospace, Pharmaceutical

As a trusted provider of custom environmental control units, Air Innovations develops precise solutions for controlling dew point and humidity. While both of these factors relate to the amount of water in the air, they describe different weather-related phenomena and affect industrial processes in different ways. This article will discuss the differences between dew point vs relative humidity and why they’re important to various industries.

What is Dew Point?

Dew point is the temperature at which point the air is completely saturated with water vapor and can hold no more. Dew point will always be equal to or lower than the air temperature.

At the dew point, the water in the air condenses into dew or frost. At certain pressures, the water vapor in the air reaches an equilibrium with liquid water and condenses at the same pace that liquid water evaporates.

What is Relative Humidity?

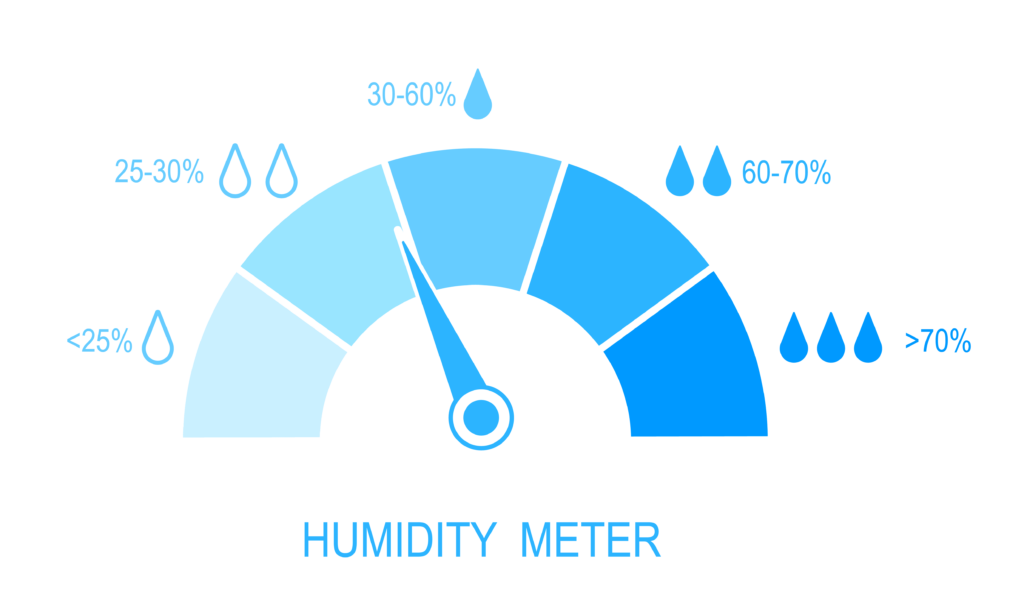

Relative humidity (RH) is a measurement of the amount of water vapor in the air, expressed as a percentage. So, a relative humidity of 100% means that the air is fully saturated and cannot hold any more water vapor. Relative humidity is proportional to temperature, and changes as temperatures and pressure increase or decrease. This means that systems with stable temperatures and pressure will have stable relative humidity.

Dew Point vs Relative Humidity

As the dew point rises, more moisture is present in the air. Relative humidity, on the other hand, is the ratio between the current amount of water vapor in the air and the maximum amount that’s possible at that temperature. Both of these factors are important to take into account when identifying the optimal moisture content of a room.

In commercial and industrial environments, dew point and relative humidity control systems deliver several crucial benefits:

- Prevents condensation on cold surfaces, as well as the mold, corrosion, and deterioration that happens as a result of these conditions

- Prevents static electricity, wood shrinkage, and paint cracking that occur when relative humidity is too low

- Keeps relative humidity in the optimal range of 25-60% RH

Dew Point and Relative Humidity Control in Critical Industries

Regulating the relative humidity and dew point is essential for many industries. At Air Innovations, we design and build precise dew point and humidity control systems for industries that include semiconductors, military, pharmaceutical, and more. We are constantly innovating to create improved solutions tailored to specific industrial environments.

Examples of our technology at work:

- Aerospace OEMs: The aerospace industry manufactures delicate technological systems that must be properly maintained with industrial cooling systems and humidification controls. These systems must adhere to narrow temperature, humidity, and dew point requirements to prevent damage or corrosion to sensitive electronics.

- Semiconductor manufacturers: Humidity and climate control systems in this type of manufacturing facility must achieve critical tolerances for temperature and humidity, in both dry or trace moisture facilities and near-saturation environments. It is particularly essential that systems using outside air provide limited humidity fluctuation rates.

- Pharmaceutical packaging plants: These environments require systems that balance high evaporative loads and heat successfully. A humidity control system in this type of facility must consistently maintain high health and safety standards.

You can learn more about our industry-specific dew point and relative humidity control systems on our industry page.

Custom Environmental Control Units from Air Innovations

Dew point and relative humidity are critical factors to control for nearly any industry. Achieving and maintaining optimal amounts of water vapor in the air protects sensitive components from damage.

At Air Innovations, we develop environmental control units that accommodate your exact needs. Our team will work with you collaboratively to design a system that meets your cost, size, and efficiency requirements while adhering to all industry regulations. To learn more, contact our team today.