Tag: Semiconductor

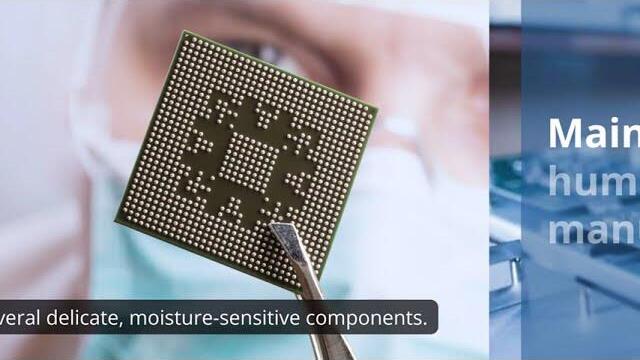

Electronics manufacturing involves the handling and assembly of several delicate, moisture-sensitive components. Maintaining optimal humidity levels during the manufacturing process is key for protecting these components from electrostatic discharge, de-soldering, and other occurrences that can decrease the quality of the final product. This article highlights the importance of effective humidity control for avoiding product damage and maintaining a safe work environment in electronics manufacturing facilities.

Reducing Electronic Damage with Humidity Control

In electronics manufacturing, both low and high humidity levels can have negative impacts on product quality as well as the safety of the work environment. Three major risks associated with incorrect humidity control are as follows:

- Electrostatic Discharge (ESD) – Electrostatic discharge describes the sudden release of static electricity when two electrically charged objects meet. In addition to damaging electronic components, ESD events can create significant safety hazards such as fires or explosions. Since low humidity levels increase the risk of ESD, it is important to maintain a humidity level of at least 30% when working with electronic components.

- De-Soldering – Low humidity levels can cause solder paste to dry too quickly, compromising the strength of the solder joint and reducing the quality of the final product. Conversely, elevated humidity levels can cause condensation to form within the components and facilitate short-circuiting. Proper humidity control minimizes these risks by maintaining a consistent relative humidity level that meets the facility’s specific process requirements.

- Brittle components – When a facility’s humidity levels are too low, components are prone to becoming brittle and weak. Keeping humidity levels in the appropriate range is key for maintaining the desired material properties.

The Benefits of Humidity Control in Electronics Manufacturing

Effective humidity control in electronics manufacturing is essential for the following:

- Maximizing production output – Proper humidity control ensures a more consistent product output, leading to greater production yields.

- Creating a safe work environment – Maintaining optimal humidity levels is critical for reducing electrostatic energy and minimizing the risk of explosions or fires.

- Prolonging the lifespan of components and devices – Tight humidity control ensures longer-lasting and higher-quality products by preventing corrosion, eliminating ESD, and keeping materials from becoming brittle.

- Maintaining compliance – Implementing an effective humidity control strategy is important for maintaining compliance with the electronics manufacturing industry’s strict requirements regarding the production environment.

The Optimal Humidity Level for Electronics Manufacturing

The ideal humidity range for an electronics manufacturing environment will depend on the following:

- Components – A facility’s humidity levels should be optimized according to the individual specifications and sensitivities of the components being manufactured and assembled.

- Location – The physical location of the application and the ambient environment will also influence the optimal humidity range. For example, applications in drier environments tend to require slightly higher humidity levels to avoid static discharge, brittle materials, and other issues caused by insufficient humidity.

For most electronics manufacturing environments, optimal humidity levels tend to range from 30% to 70%. The ideal humidity level typically depends on factors such as the ambient environment and the specifications of the electrical components and devices being manufactured. For example, maintaining a consistent relative humidity of 50% may be ideal for some manufacturing environments, whereas others may require slightly lower levels to avoid condensation and corrosion in highly moisture-sensitive components.

Contact Air Innovations for Premium Humidity Control Solutions

Maintaining the proper humidity levels in electronics manufacturing facilities is critical for preserving component quality and minimizing the risk of safety hazards. At Air Innovations, we provide state-of-the-art humidity control solutions that optimize humidity levels for a range of sensitive electronics manufacturing environments. Designed, manufactured, and tested in-house, our systems are capable of meeting even the most challenging process parameters.

To learn more about our humidity control options for the electronics manufacturing industry, please contact us today or visit our humidity control solutions page.