Heat exchangers are an effective means of absorbing heat and then transferring it from a location where it isn’t wanted. They can use several mediums to facilitate thermal transfer, most commonly air and water, but also water glycol mixtures, or steam. The material, number, and shape of the heat exchanger’s tubes can also affect heat transfer.

From air conditioners and heaters to refrigerators and industrial equipment, many devices rely on efficient and reliable heat exchangers. Exactly what is a heat exchanger, and what HVAC technologies do they support? This article will dive into these answers and more.

What are Heat Exchangers and How Do They Work?

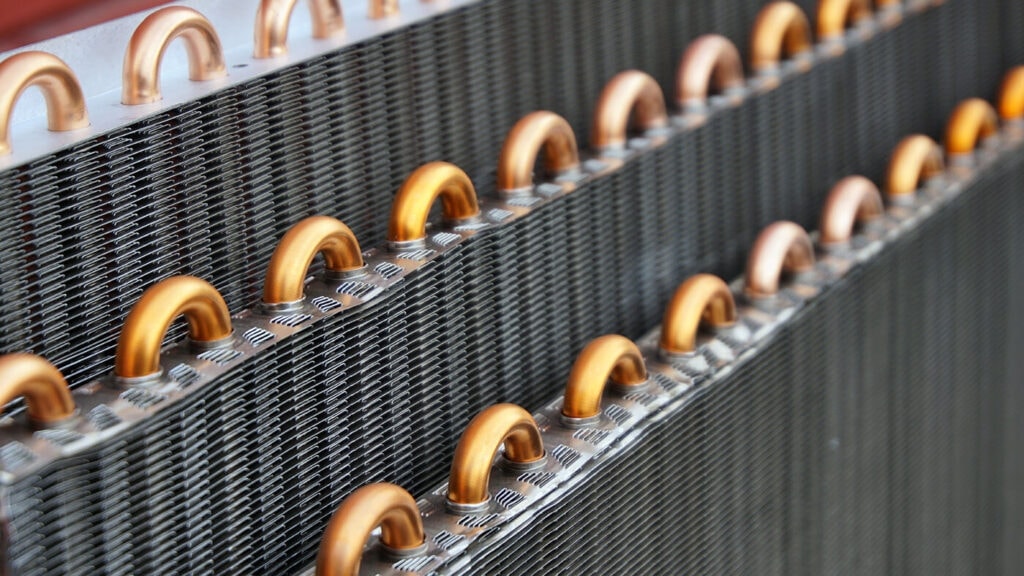

Heat exchangers, or heat exchange systems, come in a wide variety of forms for different applications. They’re typically composed of tubes and fins that exchange heat between the refrigerant, or fluid, in the tubes and the ambient temperature, making it possible to absorb and reject heat.

Heat exchangers are used to transfer heat between the indoor and outdoor air streams while keeping them physically separated as a means of cooling the indoor air. In addition, heat exchangers can also be used to heat indoor air. These systems are called heat pumps. Heat pumps reverse the flow of refrigerant and absorb heat from the outdoor environment and reject it to the indoor environment. For both cooling and heating, the heat exchanger is one of the central components of a boiler system or air conditioner.

The following are the most common types of heat exchange units:

- Tube and Fin

- Shell and Tube

- Braze plate

Heat Exchangers in HVAC Systems/Air Conditioning

In HVAC applications, heat exchange units absorb heat, which always flows from hot to cold. An air conditioning heat exchanger capitalizes on this principle by removing heat from an air supply using a series of coiled tubes carrying different types of fluids, gasses, and other mediums.

In an evaporator heat exchanger, air circulates over tubes full of refrigerant. The refrigerant absorbs heat from the air causing the liquid in the evaporator to change phase and evaporate. This removes the heat from the air left behind which then circulates into a living space. The now heated refrigerant turns into a gas and transfers heat to the condenser unit where heat is rejected into the air outside or in another space.

A compressor/pump moves the refrigerant in a closed loop system to continually chill the internal air supply and remove the heated air. These heat exchangers are driven by the compressor. The heat exchangers transfer heat from the inside to the outside.

Both the condenser (a hot heat exchanger) and the evaporator (a cool heat exchanger) are types of heat exchangers.

There are also brazed plate, or coaxial, heat exchangers, which use water to absorb, move, and dissipate heat. Heat exchangers possess remarkable versatility, making them valuable across diverse applications. However, achieving efficient thermal energy transfer hinges on the meticulous design of heat exchange systems based on your application requirements.

Main Benefits

From internal climate controls to preventing equipment from overheating, efficient heat exchangers carry several benefits:

- Less energy is required to cool or heat a structure

- A more energy-efficient HVAC system

- Facilitating the bulk of the heat exchange process

- More efficient machine and motor operations

Air Innovations’ Project Examples

- Laser Machine – Semiconductor Etching Application: An Air Innovations heat exchanger controlled the heat emitted by a laser etching device. By moving heat away from the laser, the etching machine functioned more efficiently, making the microchip etching process more accurate.

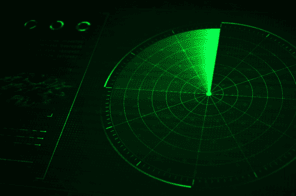

- Military Applications – Radar Systems: Our heat exchange units similarly cool down electronics that control military-grade radar systems. In such cases, the radar’s electronics will shut down if they reach a certain temperature, as a self-protection mechanism. By preventing the radar system from overheating, it ensures the military can continually keep essential components operable. Using a micro-channel coil type design, we were able to maintain more contact between the refrigerant and the tubes, which are made of small diameter and aluminum design. By maximizing surface area with more, smaller tubes, our heat exchanger removes thermal energy with maximum efficiency.

Contact Air Innovations for Premium Environmental Control Solutions

Air Innovations provides all design, testing, and manufacturing services required for efficient and reliable environmental control units and custom HVAC solutions. Our heat exchange units meet the precise tolerance windows required for high-quality environmental controls, and we can custom design heat exchange systems for a variety of equipment.

To learn more about how heat exchangers facilitate the transfer of thermal energy and provide fine-tuned control of heated and cooled air, contact us and tell one of our dedicated service technicians about your heat exchange system needs.