When it comes to controlling aerospace environments, there are no do-overs.

Mention heating and air-conditioning and most people think first of human comfort. But when it comes to controlling environments in aerospace projects, the fine line between success and catastrophe often depends on maintaining far more precise conditions than the broad range tolerated by people.

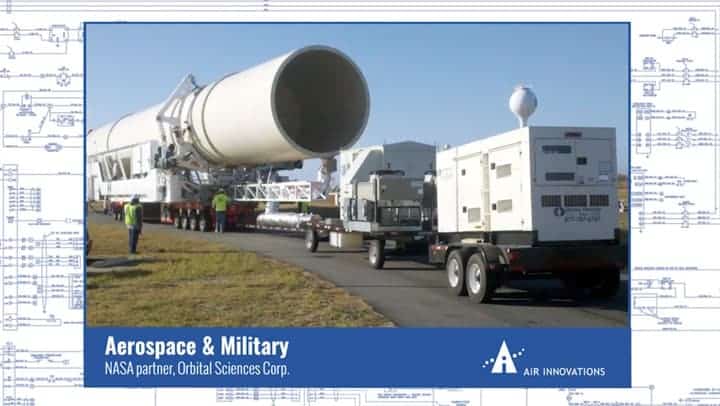

Take, for example, a project by specialty environmental-control company Air Innovations working with NASA partner Orbital Sciences Corp. on prelaunch for the Antares rocket system. The easy part? Keeping the launch area at a comfortable 70°F and 50 percent relative humidity for technicians working on the rocket. What really tested the combined expertise of Air Innovations engineers was controlling an environment where no humans would tread, deep inside the rocket’s fueling system.

Low dew point, high stakes

Because of the fuel’s frigid temperature, engineers had to figure out how to bring the rocket to a bone-dry dew point of minus 22°C just prior to launch. “Our job was to get all of the moisture out,” says Mike Wetzel, P.E., CEO and president of Air Innovations. “If you fuel a rocket with any moisture present, that moisture would condense out of the air as ice on all the piping. That can bring a rocket down.”

The company’s solution—a pair of customized environmental control units (ECUs) surrounding an in-line desiccant dryer—is just one example of the innovative thinking required to craft failsafe solutions in an environment devoid of second chances.

While Air Innovations creates customized clean environments for other highly demanding sectors, such as pharmaceuticals and semiconductors, “What’s unique about aerospace is the level of specific control,” Wetzel says. “Sometimes, that means building in 100% redundancy. We have a project right now where there will literally be two of everything. Every system must run all the time, so the backup can come on almost immediately if necessary.”

Other aerospace projects may call for keeping a delicate payload absolutely clean and stable on a 500-mile highway journey through heat, snow and dust, or removing every trace of corrosive salt from seaside air. And all of it with the safety of a $1 billion satellite at stake. As stressful as that may sound, Wetzel says, “Those challenges are what’s so cool about our business.”

Learn more about our aerospace environmental control. For more information, contact us.

The power of partnership

Another benefit of working in aerospace, says Sam Brown, OEM sales manager for Air Innovations, is the close relationships forged with highly demanding clients. “It’s really more of a partnership,” Brown says.

“Think about the amount of time and money invested in aerospace projects,” Brown says. “This is a small, close-knit community. You have to win the Super Bowl each time out. Because if you mess up—if that payload gets into space damaged, or a rocket blows up on a pad—and it’s your fault, you’re done. We have one shot to make it right each time.”

On the other side of that equation, of course, is the pure satisfaction of devoting all of your expertise, discipline and passion to an aerospace defense project that will help keep the country safe, or a space mission that will advance human knowledge. Brown points to Air Innovations’ current work creating clean environments where elements of the new Webb space telescope are being built.

Each time out, he says, “You’re helping to achieve something that’s never been done before.”

For more information on Air Innovations and environmental control in aerospace, please see our white paper, “Controlling the Environment in Aerospace,” at airinnovations.com, or give us a call at 800-825-3268.