Negative or positive pressure rooms are often necessary to prevent contamination and maintain a climate-controlled environment in various applications. While these rooms are somewhat similar, there are certain differences between their designs and requirements. Here we’ll give an overview of both of these types of environments, including their intended applications and design requirements.

Negative Pressure Rooms

Negative pressure rooms have air pressure that is lower than the external air pressure. Negative pressure is achieved through the use of an exhaust system that frequently includes a high-efficiency particulate air (HEPA) filter connected to a sealed room. These rooms can trap potentially dangerous particles to prevent cross-contamination in external air. This is why they’re often used to isolate infected patients while keeping people outside of the room consistently safe.

Design Requirements

Negative pressure rooms are designed to contain airborne infections. To do so, there are various design requirements that these rooms must follow, which are outlined by CDC Guidelines, ASHRAE standards, and Healthcare Design Construction Guidelines. As summarized in these guidelines:

- Negative pressure rooms must undergo at least 12 total room air changes every hour.

- They need to maintain a negative pressure differential of at least 0.01’’.

- Exhaust from these rooms and any connected anterooms or toilet rooms needs to travel directly outdoors with no chance of contaminating exhaust from other spaces.

- If an anteroom is included in the setup, airflow needs to travel into the anteroom via the corridor. From there, it should be channeled into the patient isolation room.

- The quantity of air exhaust needs to be higher than the supply airflow to maintain a consistent pressure differential.

- The exhaust grille must be located in the ceiling and near the head of the bed.

- All exhaust air must be discharged through a HEPA filter if the fan is below the roof line.

Misconceptions About Negative Pressure Rooms

One potentially dangerous misconception about negative pressure rooms is that medical personnel are safer when performing aerosol-generating procedures on patients in these rooms. This is due to the Centers for Disease Control and Prevention (CDC) recommendation that these procedures be performed in isolation rooms. However, negative pressure rooms do little to protect individuals inside the room. Their main purpose is to help protect people outside of the room by keeping aerosols and other particles within the room.

Positive Pressure Rooms

A positive pressure room is intended to protect patients from infectious diseases if they’re immunocompromised. While this type of room is somewhat similar in concept to negative pressure rooms, it features certain differences in its function and design. Positive pressure rooms contain a higher pressure in the containment area than the external environment, preventing air from leaving the room and circulating back inside. This prevents occupants in the room from being exposed to any outside contaminants, including potentially harmful particles and germs.

Design Requirements

Positive pressure rooms must follow various design requirements to keep patients protected from outside contaminants. Included in these requirements are the following elements:

- Positive pressure rooms require at least 12 air changes every hour.

- They must maintain a minimum positive pressure differential of 0.01’’.

- If anterooms are used, the airflow must travel to the anteroom from the patient room and then into the adjacent corridor.

- Normally, a 150 to 200 CFM airflow difference is sufficient for maintaining the ideal pressure differential in these rooms.

- HEPA filters are required to supply clean air. These filters are normally located at the room’s supply terminals or the main air-handling unit.

- Airflow to the room needs to stay at a constant volume for consistent ventilation.

Create Custom Positive and Negative Pressure Environments with Air Innovations

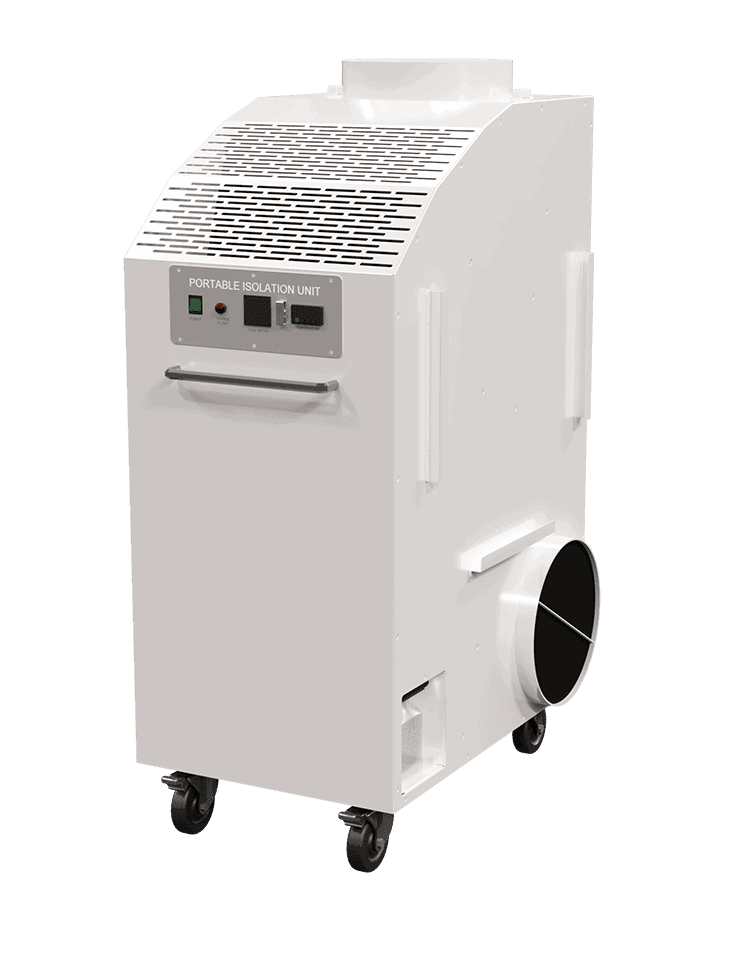

If you require flexible positive or negative pressure rooms for your application, Air Innovations has the expertise and solutions you need. Our IsolationAir® unit offers a portable contamination control system that can efficiently convert standard-sized patient rooms into either positive or negative pressure environments. Some of the features of our IsolationAir® system include ductwork, UV sterilization, and HEPA filtration connections. The system also allows for temperature control, isolating the room from the central HVAC system.

Learn how Community Health Net created Negative & Positive Pressure Environments to create better patient outcomes and safer spaces for employees and patients. Watch the video below.

For more information about our systems, contact us today. You can also request a quote to get started on a custom solution for your project.