This article was co-produced by GlobalSpec and Air Innovations

Cleanrooms are needed in several industries and laboratories for a variety of reasons. For example, medical or pharmaceutical products must be devoid of harmful pathogens that may increase the risk of infections for patients; semiconductor circuits can be made inoperable by submicron-size contaminate particles introduced during manufacturing; certain biological or chemical products may require the precise control of temperature, humidity or air pressure to ensure proper and consistent chemical reactions; and sensitive optical and electronic equipment may require testing and calibration in highly controlled thermal environments. These and other applications require the use of cleanrooms or sterile environments.

Typical cleanrooms require a substantial capital investment in equipment and facilities for air filtration and air conditioning in order to control airborne particles, such as dust, microbes, aerosols or chemical vapors, or to ensure proper temperature, humidity and air pressure. Under certain circumstances, however, budget, time, and space constraints make it impossible to construct a cleanroom, and it is necessary to have a rapidly deployable or portable cleanroom solution.

This article reviews requirements for standard cleanrooms and highlights how some of the most stringent cleanroom requirements can be satisfied on demand with the Air Innovations SSC 4500 Sterile Storage Cabinet system.

Cleanroom Standards

Cleanrooms are closed environments that are designed to enable the strict control of environmental contaminants, temperature, humidity or air pressure. They are typically classified according to the cleanliness level of the air inside of them. In the U.S. and Canada, the ISO 14644-1 classifies cleanrooms in accordance with the quantity and size of particles per volume of air, with ISO 1 being the “cleanest” class and ISO 9 being the “dirtiest” class. The alternative U.S. Federal Standard 209 has equivalents for the ISO classes, where Class 1 is equivalent to ISO 3, and Class 100,000 is equivalent to ISO 8. For purposes of comparison, an ISO 1 cleanroom will allow 10 0.1-micron particles per cubic meter, whereas an ISO 6 cleanroom will allow one million (1×106) 0.1-micron particles per cubic meter.

Cleanrooms use special equipment, such as high efficiency particulate air (HEPA) filters for environmental control. These are a type of pleated mechanical air filter that can theoretically remove at least 99.97% of dust, pollen, mold, bacteria and any airborne particle with a minimum size of 0.3 microns or greater. They are rated in terms of “minimum efficiency reporting value,” or MERVs, based on the filter’s ability to capture particles between 0.3 and 10 microns. HEPA filters with MERV ratings of 1 to 4 are capable of only 20% of 0.3 to 10.0 micron particles, whereas filters with MERV ratings of 16 are capable of up to 75% of 0.3 to 1.0 micron particles.

The monitoring and control of temperature and humidity is essential to reduce microbial growth, control static charge build-up, and minimize moisture condensation and water absorption, among other things. This is accomplished using highly precise temperature, humidity and air pressure sensors and controllers together with standard heating, ventilation and air conditioning pumps, compressors and air handlers. In most cleanrooms, it is desirable to have a positive (higher) air pressure inside the cleanroom, so as not to suck in potential contaminants from the external environment through air leaks or if the cleanroom doors are opened. This is accomplished with high capacity fans that can clean, filter and condition the outside “make up” air and enable several air changes per hour.

Cleanrooms that require sterilization or disinfection may incorporate ultraviolet germicidal irradiation (UVGI), which is effective in killing or inactivating several different types of microorganisms, such as bacteria, viruses, molds and other pathogens. These devices may be placed in the air conditioning system, in the water supply, or within the cleanroom to neutralize microorganisms in the circulating air, water or on surfaces.

Portable cleanrooms

The specialized HEPA filtering, air conditioning and germicidal control equipment used in cleanrooms have typically required a significant capital investment in permanent facilities to house the cleanroom. Another alternative may involve use of modular walls and equipment that can be constructed or assembled inside rooms within buildings to quickly provide a temporary cleanroom or sterile environment. Yet another alternative may involve use of a portable cleanroom, which can be the size of a trailer that may be implemented in the field.

Numerous requirements abound that express the need for miniaturized and highly portable cleanrooms or sterile environments. For example, in the aerospace and defense industry, sensitive optical and electronic equipment may require calibration in highly controlled environments. However, it may be necessary to perform this calibration in the field or while it is installed within a larger system, such as an aircraft, that cannot be introduced into a cleanroom. In the medical industry, pandemics, quarantines and other medical emergencies may require the rapid deployment and construction of temporary field hospitals in tents, cruise ships, schools and large convention centers that lack sterile or controlled environments for the storage of medicines or the segregation of contagious pathogens. In the semiconductor industry, portable cleanrooms may be required for the storage or transport of wafers or photolithography masks between manufacturing operations or facilities.

Air Innovations sterile storage cabinets

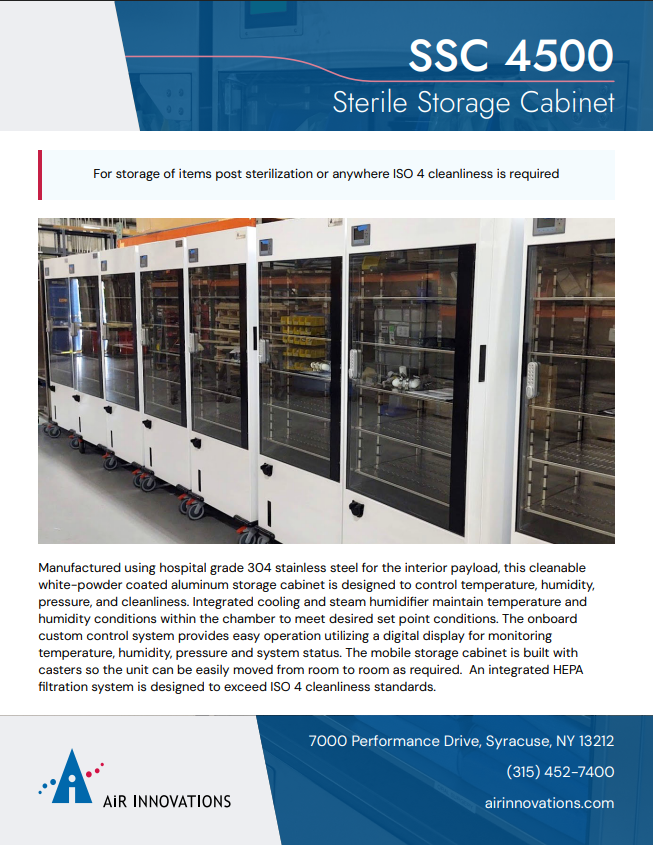

To address the need for portable and sterile environments, Air Innovations has developed the SSC 4500 Series sterile storage cabinet.

This compact system was designed for maximum flexibility, ease of use and transportability. This system saves time and money by preventing unnecessary reprocessing by keeping sterile materials and equipment within the proper environment without the need to retrofit an existing space to meet strict temperature, humidity, pressure and particulate requirements.

Specific features and capabilities include the following:

- Temperature control range: 66° F to 72° F

- Humidity control range: 20% to 60% relative humidity via integrated cooling and steam humidifier

- Positive pressure: Up to 0.03 in-H2O with at least 250 air changes per hour

- Particulate control: Integrated HEPA filtration system is designed to exceed ISO 4 cleanliness (or better in controlled environments)

- Microbial control: Optional UV-C light can be installed within HEPA air handler

- Portability: Unit mounted on casters for easy movement and relocation

- External connections: 120 VAC (15 A) with no additional hardwired electrical or plumbing connections

- User interface: Onboard custom control system provides easy operation through a digital display for monitoring and control of temperature humidity

- Materials and cleanability:

- Interior: Hospital grade 304 stainless steel

- Exterior: White powder coated aluminum

- Noise: 55 to 59 dBA at 1 meter

- Standards compliance:

- VHA Directive 1116(2) – Sterile Processing Services

- CSA Z314.15-10 — Storage, Transportation, and Distribution of Single Use and Reusable Medical Devices

- ANSI/AAMI ST79-2006 — Guide to Steam Sterilization

- ANSI/ASHRAE/ASHE 170-2017 — Ventilation of Health Care Facilities

- UL 60601-1 — Medical Electrical Equipment, Part 1: General Requirements for Safety

The SSC 4500 series sterile storage cabinet meets the needs for highly deployable on-demand clean room environments in several industries.

Note: The SSC4500 is not intended for use in the diagnosis of disease or other conditions or in the cure, mitigation, treatment, or prevention, of disease in humans or in other animals.

Contact Us For Your Sterile Storage Needs

Having access to the right storage keeps your equipment, patients, and business safer. We have leasing options available, so you can store your items when you need it the most. Contact us today to find the right sterile storage cabinet that fits your requirements.

Learn more about using our Sterile Storage Cabinets in hospital environments. Interested in how our Sterile Storage Cabinet came to be? Read our case study regarding the process of designing and manufacturing the product.