At Air Innovations, we’ve designed, manufactured, and tested custom environmental control solutions for OEMs and non-OEMs for over 30 years. This extensive experience provides us with the knowledge and skills needed to deliver appropriate systems for a wide range of industries. One of the key markets we serve is the healthcare industry. Healthcare professionals know they can rely on us for products that keep their patients and personnel safe and healthy, such as hospital isolation room systems.

Below, we provide an overview of hospital isolation rooms, outlining the types available and key considerations to keep in mind when building one for a healthcare facility. Additionally, we highlight the products we offer that can be used to help build isolation rooms.

WHAT ARE HOSPITAL ISOLATION ROOMS?

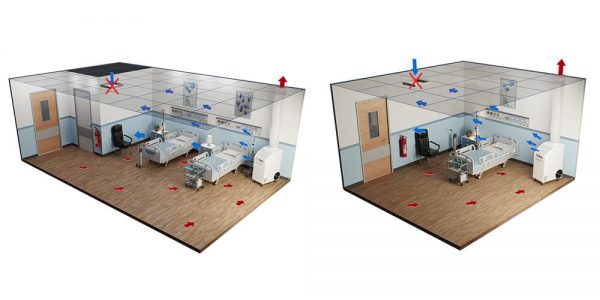

In hospitals and other healthcare facilities, controlling the spread of infectious diseases is critical to keeping patients, personnel, and visitors safe and healthy. An important element of a comprehensive infection control strategy is the use of isolation rooms. These specialized rooms are designed to decrease the likelihood of cross-infection among people within the facility by controlling the flow of air within the room to reduce airborne infectious particle levels. They can achieve this goal in a number of ways, including by controlling the quantity and quality of intake or exhaust air, maintaining an air pressure differential between adjoining areas, directing airflow in a specific pattern, diluting room air with large volumes of clean air, and cleaning the air with high-efficiency particulate air (HEPA) filters.

TYPES OF HOSPITAL ISOLATION ROOMS

Isolation facilities can be configured in several ways, including the following:

- Standard Rooms. These rooms utilize standard room (neutral) air pressure levels. They have normal HVAC systems and may or may not have a clinical handwash sink, en suite shower and toilet facilities, and a self-closing door. While they are generally used for patient contact isolation applications, they can be used for normal patient care when isolation is not required.

- Airborne Infection Isolation (AII) Rooms. These rooms—also referred to as infectious isolation rooms—utilize a negative-pressure differential. They have lower pressure levels than adjacent rooms so air will rush inward rather than outward when the room is opened. This design prevents airborne infectious particles from escaping into other areas of the healthcare facility. They are employed as single-occupancy rooms to isolate patients with suspected or confirmed airborne-transmissible infections.

- Protective Environment (PE) Rooms. These rooms utilize a positive-pressure differential. They have higher pressure levels than adjacent rooms so air will rush outward rather than inward when the room is opened. This design prevents airborne infectious particles from entering the room from other areas of the facility. They are utilized to protect immune-compromised patients from airborne-transmissible infections.

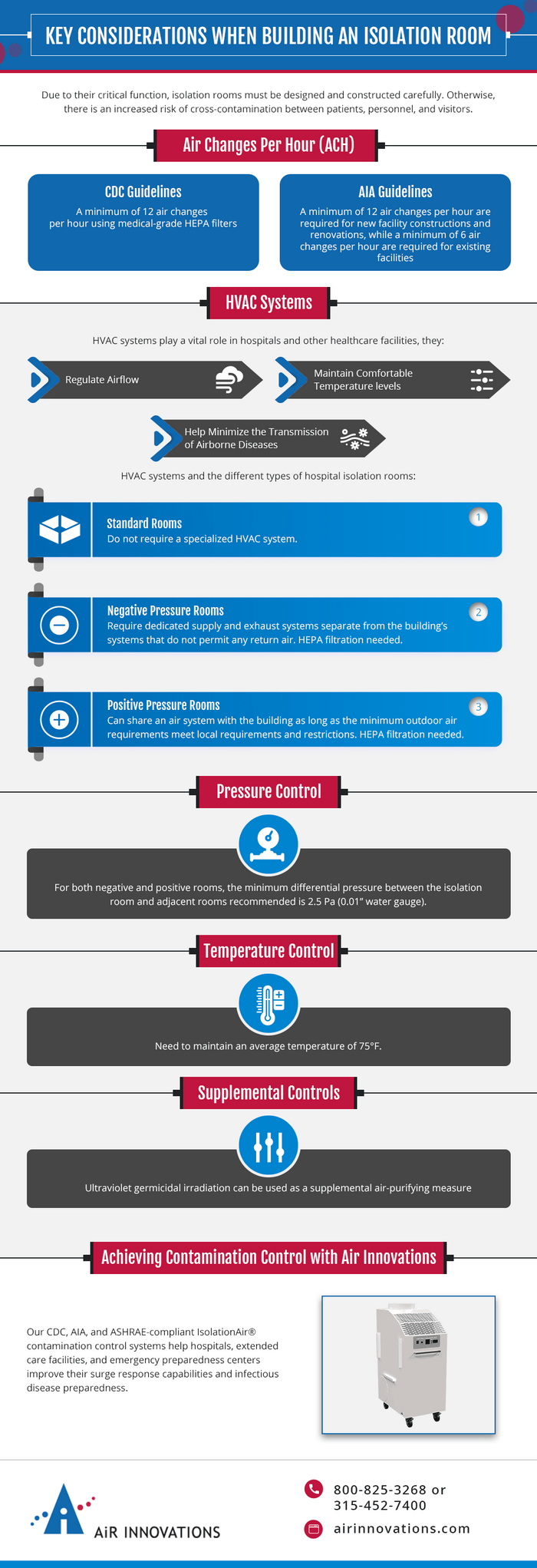

KEY CONSIDERATIONS WHEN BUILDING AN ISOLATION ROOM

Due to their critical function, isolation rooms must be designed and constructed carefully. Otherwise, there is an increased risk of cross-contamination between patients, personnel, and visitors. While there are many factors to consider to ensure an isolation room will work properly, some of the key ones include air changes per hour, HVAC, pressure control, temperature control, and supplemental controls.

AIR CHANGES PER HOUR (ACH)

As per the infectious disease control guidelines outlined by the Centers for Disease Control (CDC), isolation rooms should have a minimum of 12 air changes per hour using medical-grade HEPA filters. These filtration units are designed to remove 99.97% of airborne particles that are ≥0.3 µm in diameter. The American Institute of Architects (AIA) further specifies that a minimum of 12 air changes per hour are required for new facility constructions and renovations, while a minimum of six air changes per hour are required for existing facilities.

HVAC

HVAC systems play a vital role in hospitals and other healthcare facilities. In addition to regulating airflow and maintaining comfortable temperature levels, they also help minimize the transmission of airborne diseases. When properly implemented, they can prevent the spread of contaminant-laden air through air purification, improved ventilation, and airflow control.

- Standard rooms do not require a specialized HVAC system.

- Negative pressure rooms require dedicated supply and exhaust systems separate from the building’s systems that do not permit any return air. A HEPA filtration should be connected to the supply system if the room will be used for isolating immunosuppressed patients. Additionally, the air conditioning system should be connected to an emergency power supply to prevent depressurization in the event of power loss.

- Positive pressure rooms can share an air system with the building as long as the minimum outdoor air requirements meet local requirements and restrictions. However, the supply air inlet should be fitted with a HEPA filter.

PRESSURE CONTROL

The recommended minimum differential pressure between the isolation room and adjacent rooms is 2.5 Pa (0.01” water gauge) for both negative and positive rooms.

TEMPERATURE CONTROL

Isolation rooms must be appropriately heated or cooled to maintain an average temperature of 75°F.

SUPPLEMENTAL CONTROLS

Ultraviolet germicidal irradiation can be used as a supplemental air-purifying measure.

ACHIEVING CONTAMINATION CONTROL WITH AIR INNOVATIONS

We offer a broad selection of products that help control contamination in healthcare facilities. For example, our IsolationAir® portable contamination systems can be used to turn standard-sized rooms into negative-pressure or positive-pressure isolation areas for patient care or containment in as little as 30 minutes. They quickly and easily create a sterile environment in an isolated space that prevents cross-contamination, ensuring patients and personnel are better protected against infectious diseases. IsolationAir systems have several key features:

- Pressure control to create a positive or negative pressure differential between the room and adjoining spaces

- HEPA filtration unit to capture and remove airborne contaminants

- UV-C sterilization unit to deactivate viruses and bacteria that have accumulated on the HEPA filter

- Heating/cooling to keep patients comfortable within the space

The system meets all the relevant guidelines outlined by the following organizations:

- Centers for Disease Control (CDC)

- American Institute of Architects (AIA)

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE)

Download our IsolationAir brochure for more details about our line of standard hospital contamination control systems.

CONTACT US FOR YOUR ISOLATION ROOM ENVIRONMENTAL CONTROL NEEDS

In medical facilities, dedicated isolation rooms are a critical tool for controlling airborne disease transmission. These spaces can be expensive to build and often require extensive airflow control measures to prevent cross-contamination with the rest of the facility effectively.

At Air Innovations, we understand the importance of airborne disease control in the healthcare industry. Our CDC, AIA, and ASHRAE-compliant IsolationAir® contamination control systems help hospitals, extended care facilities, and emergency preparedness centers improve their surge response capabilities and infectious disease preparedness. The portable units can be quickly and conveniently deployed to convert standard rooms into isolated environments for a number of applications, saving healthcare facilities time and money.

To learn more about our environmental control solutions and how they can benefit healthcare facilities, contact us today.