Controlling temperature and humidity is crucial to the longevity and performance of semiconductors. Semiconductors are often fragile and operations can be impacted by minute temperature fluctuations or mild contaminants such as dust or dirt.

Over the past several decades, Air Innovations has stayed in step with the innovations of semiconductor fabricators, supplying temperature and humidity control systems to meet the critical needs of the ever-changing industry.

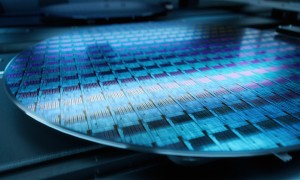

The Semiconductor Industry

It is impossible to predict where the theoretical boundaries of semiconductor innovations lie, but given the history of developments, it is easy to predict that the limits will continue to expand. Breakthroughs in the 1980s produced devices at the level of a single micron (1,000 nanometers). In less than 30 years, the industry now produces semiconductor devices with capacities in the range of 14 nanometers.

As developers move into 2020, their sights are set on cutting those overly obese devices in half. Predicting beyond 7 nanometers will no doubt prove extremely challenging. Frankly, we cannot wait to see what happens next. Air Innovations focuses our attention on providing solutions to the challenges each exciting innovation creates.

Types of Semiconductor Environments

Whether you are working in design or quality in a Semiconductor application, you need a partner who understands your challenges and knows how to help you achieve your goals. Air Innovations supports customers within a variety of Semiconductor environments and applications. Our customers in the semiconductor industry are usually looking for environmental control in one of these areas:

1. Critical Tolerances on Temperature / Humidity

Most of our customers working with environmental control in a semiconductor environment require material stability and measurement accuracy that comes from semiconductor temperature control. Whether you work in lithography, photomask repair, or another area of interferometry, we design to meet your system goals. Our temperature control systems have been as precise as ±0.02°C and ensure no excess heat affects your processes or systems.

2. Wet / Near Saturation Environments

Some of our customers work in semiconductor environments that require very high humidity to maintain material properties and to prevent residual buildup. Having a partner experienced with maintaining the near-saturation environments that can exist in semiconductor applications from electrospinning to chemical mechanical planarization (CMP) can help you achieve your design goals faster and with greater confidence.

3. Dry / Trace Moisture Environments

Sometimes semiconductor processes require a trace moisture environment to maintain material properties essential in precision bonding, such as in multi-wafer stacking in a non-vacuum environment. Air Innovations can help you sustain the low-humidity environment you need to meet your process parameters.

Download our semiconductor whitepaper:

We have designed semiconductor temperature control systems and humidity control units for all of these special requirements in both production and test environments. Contact us for more information about our capabilities with temperature and humidity control system solutions for semiconductors.

Download WhitepaperThe Effect of Temperature on Semiconductors

Semiconductors have a negative temperature coefficient for resistance—this means that conductance increases and resistance decreases when heated. Heat applied to semiconductor material causes the separation of the outermost electrons from the atomic nucleus of the material compounds due to an increase in energy. These free electrons become conductive.

As the number of free electrons increases, there will be an associated drop in resistance. Maintaining temperatures within a specific range is necessary to facilitate the proper function of electronic devices that operate using semiconductors. Tightly regulated temperature control is even more critical in semiconductor manufacturing.

Our Semiconductor Environment Control Capabilities

To accommodate our customers who develop and manufacture semiconductors, our customized environmental control units (ECUs) facilitate stringent temperature and humidity tolerances, including:

- Control tolerances of +/- 0.02º C

- Setpoint temperature ranges between 19º C and 23º C

- Relative humidity tolerances of +/- 0.5% RH

- Airflow ranges up to 4000 CFM

The photomasks used in semiconductor lithography require cleaning and repair using a process known as nanomachining, which uses interferometry to scan for defects in need of repair. Minor differentiations in the surrounding temperatures during wafer scanning can produce highly inaccurate readings. Our ECUs stabilize these readings by providing temperature variations within the range of 0.02º C.

Semiconductor System Design Considerations

Given customer specifications, our expert team can design and build an environmental control unit to meet the needs of virtually any semiconductor manufacturing application. We offer a wide range of ECU solutions, including off-the-shelf, semi-custom, and fully custom units in standalone or mounted configurations.

From the initial design to delivery of a complete system, our team can focus on one of two key design factors: flexibility or future requirements. By designing an ECU system with flexibility in mind, the customer is better able to accommodate any alterations that may be required or desired in the future. These alterations could be a result of new technologies or expanded capacities. By anticipating future requirements when designing the system now, the customer is less likely to require any alterations to meet changing needs or wants.

Which of the two factors we focus on depends on the customer:

- If the customer knows what the state of their business and customer demand will be in the future, an over-spec design is most suitable.

- If the customer expects more variable future trends, a flexible design is more appropriate.

Temperature and Humidity Control Solutions from Air Innovations

Air Innovations provides custom environmental control units with precise temperature and humidity levels to meet the specific needs of each client’s unique application. Our ECUs are vertical or horizontally shaped and sized to fit inside or adjacent to the fabrication environment. ECUs from Air Innovations use the most advanced ULPA filters with the capacity to remove 99.999% of particles larger than 0.12 microns, combined with molecular filtration at the highest level of sensitivity to prevent harmful gases from affecting critical processes.

Temperature and humidity control are critical elements in semiconductor development and fabrication. Precise levels of environmental factors are necessary for the longevity and performance of semiconductor devices.

Other important requirements for some design engineers in semiconductor applications include the following:

- Flexible packaging

- Orientation (vertical/horizontal/integrated)

- Complex fan filtration (integrated HEPA and molecular filtration)

- Frequency control

- Lighting

We have designed semiconductor temperature control systems and humidity control units for all of these special requirements in both production and test environments. Contact us for more information about our capabilities with temperature and humidity control system solutions for semiconductors.

For more information on semiconductor temperature control systems & humidity regulation, read the case studies below: