Humidity control is a crucial consideration in industrial applications. Controlling relative humidity (RH) at optimal levels helps to keep equipment operating efficiently and protects products from defects, damage, or contamination.

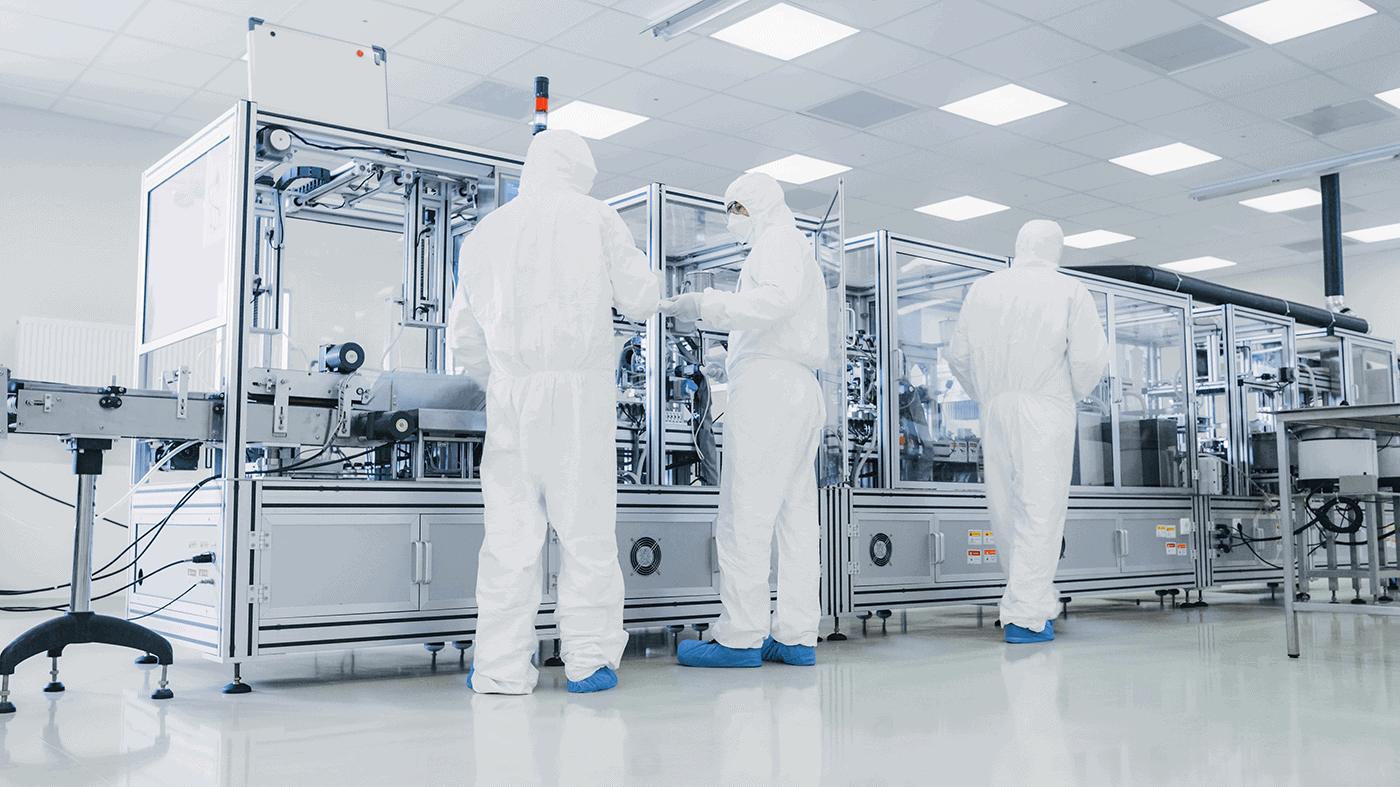

At Air Innovations, we provide custom humidity control solutions for manufacturers in aerospace, medical, semiconductor, pharmaceutical, and other industrial settings. Our temperature and humidity control systems have been trusted by some of the biggest names to protect their equipment and products from environmental instabilities.

Learn more about our capabilities and why a custom solution is beneficial for a range of applications.

Precise Humidity Control Solutions From Air Innovations

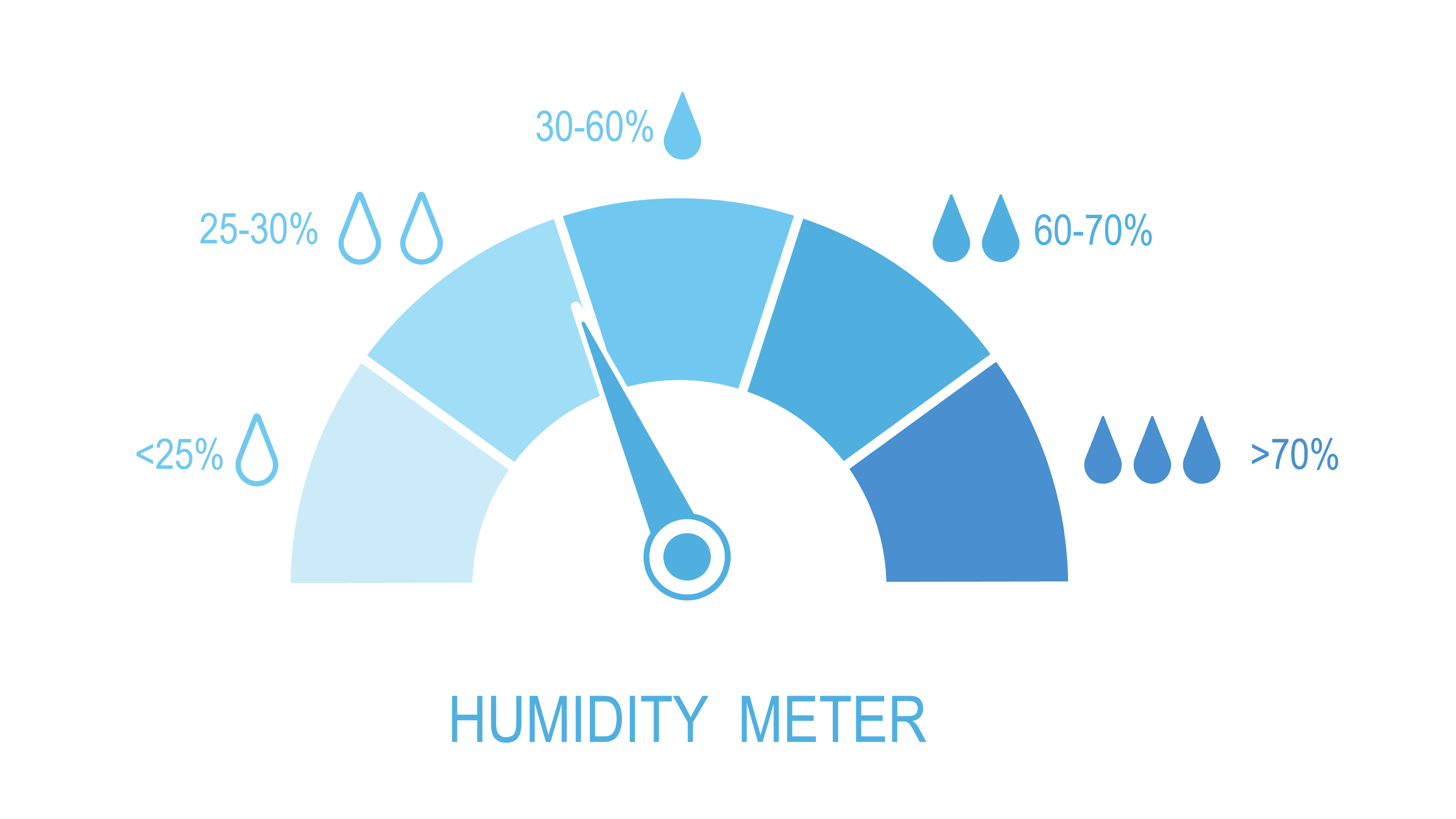

Our high-precision humidity control systems can humidify or dehumidify a space. A range of relative humidity levels can be achieved and maintained, from desiccant levels to 95% RH, within +/- 0.5% RH. Dew point tolerances from -60°C to near saturation point can also be achieved.

In addition to humidity control, our complete environmental systems address temperature, filtration, and pressure. The team at Air Innovations can design, build, and install systems to meet unique or specialized requirements including the following:

Humidification and dehumidification

Ultrasonic or steam humidification

Custom sizes and configurations

Explosion-proof design

Precise or broad range temperature control

Mil-Spec or Semi Standards

Stationary or portable systems

Filtration

Positive or negative pressure

WHY CHOOSE CUSTOM? THE BENEFITS OF TAILORED HUMIDITY SOLUTIONS

Standard, off-the-shelf humidity and HVAC systems can’t always achieve the precise RH required for highly specialized applications. A custom system meets your exact needs and offers several benefits:

PRECISION

A tailor-made system makes it possible to set and hold exact humidity levels for an application.

UNIQUE SPECIFICATIONS

Systems can be designed to meet strict or unique requirements, such as explosion-proof materials, cleanroom facilities, or regulations for products or processes.

RISK REDUCTION

Improper humidity conditions can lead to excessive static buildup or brittle components if too low, or condensation, corrosion, mold, and improper drying if too high. A custom solution targets specific risks and minimizes them. System redundancies or backups can also be incorporated to reduce risks associated with system failure or downtime.

SYSTEM UPDATES AND SCALABILITY

A custom system can be built to accommodate future modifications, expansions, or adaptations to suit changing needs over time.

Humidity Control in Different Industrial Applications

Different industries and applications require different humidity levels. Some processes require more humidity while others require a drier environment. In both cases, the goal is always to provide a consistent and suitable environment to maintain safety, operational standards, or equipment efficiency.

If an application becomes too dry, static discharge is possible. Location also affects humidification, for example, if a facility is located in a desert area or other dry parts of the world, it may be necessary to raise humidity levels and control them very closely.

In contrast, if too much humidity is present, the excess moisture may cause walls and equipment to sweat. This can lead to corrosion outside and inside equipment and structural damage to the facility. Steps must be taken to reduce humidity levels.

Some of the industries we serve and sample applications include the following:

- Aerospace: In the aerospace industry, if your rocket requires tight tolerances and the humidity control does not work properly, crystallization may occur inside the rocket which could result in the loss of the overall system. In addition, aerospace OEM facilities require large industrial cooling systems to maintain proper conditions for manufacturing delicate instrumentation and electronics, including narrow ranges for temperature, dew point, and humidity. And finally, payloads inside a rocket, such as satellites, generally require humidity control at all times to prevent any harmful effects of unacceptable humidity levels prior to rocket launch.

- Military and Defense: Proper humidity control is required to protect electronics and delicate instrumentation from static buildup in overly dry environments and prevent corrosion in very wet environments. For example, a laser used in a dry environment is susceptible to static discharge, which can burn out electronics if the humidity is not corrected.

- Pharmaceutical: To keep processing equipment suitably dry and to limit moisture in manufacturing pills, capsules, and devices, humidity control is required. For example, excess moisture can cause pills to become sticky and not to dry properly, which can affect the coating process and result in product loss.

- Semiconductor: Climate control systems in semiconductor facilities must meet critical tolerances for humidity and temperature in both near-saturation and dry or trace-moisture environments. If an application uses outside air, it is necessary to minimize fluctuations in humidity levels throughout the process.

Air Innovations industrial humidity control systems can be built to meet the needs of any industry, whether your facility must maintain compliance with regulatory standards, or requires varied humidity levels in separate regions of the facility. We continually innovate to create humidity control systems that are optimized for specific industrial environments.

ADDITIONAL RESOURCES ON INDUSTRIAL HUMIDITY CONTROL

Case Studies

Blog Posts

CONTACT AIR INNOVATIONS FOR PREMIUM ENVIRONMENTAL CONTROL SOLUTIONS

Choose custom humidity and environmental control solutions from Air Innovations. We specialize in humidity, temperature, pressure, and filtration systems for processes and applications where a standard, off-the-shelf HVAC system simply will not suffice. We also provide a line of standard solutions for unique settings such as cleanrooms, florist facilities, and hospitals.

Contact us today to learn more about custom humidity control systems, or to request a quote.