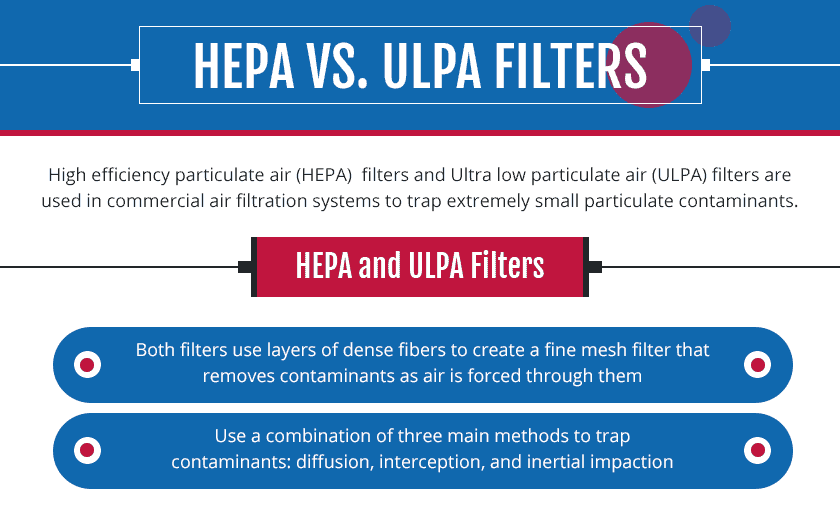

All heating and cooling air duct systems naturally collect dust and contaminants. Clean rooms, such as those used in the electronics, pharmaceutical, and medical industries, require a controlled environment free of dust, airborne particles, and other contaminants. Ultra low particulate air (ULPA) filters and high efficiency particulate air (HEPA) filters are used in commercial air filtration systems to trap extremely small particulate contaminants.

ULPA vs. HEPA Filter

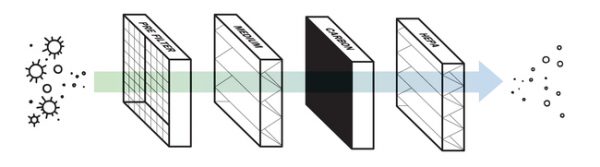

ULPA and HEPA filters share many characteristics but differ in some crucial aspects. Both filters use layers of dense fibers to create a fine mesh filter that removes contaminants as air is forced through them. Both HEPA and ULPA filters use a combination of three main methods to trap contaminants: diffusion, interception, and inertial impaction.

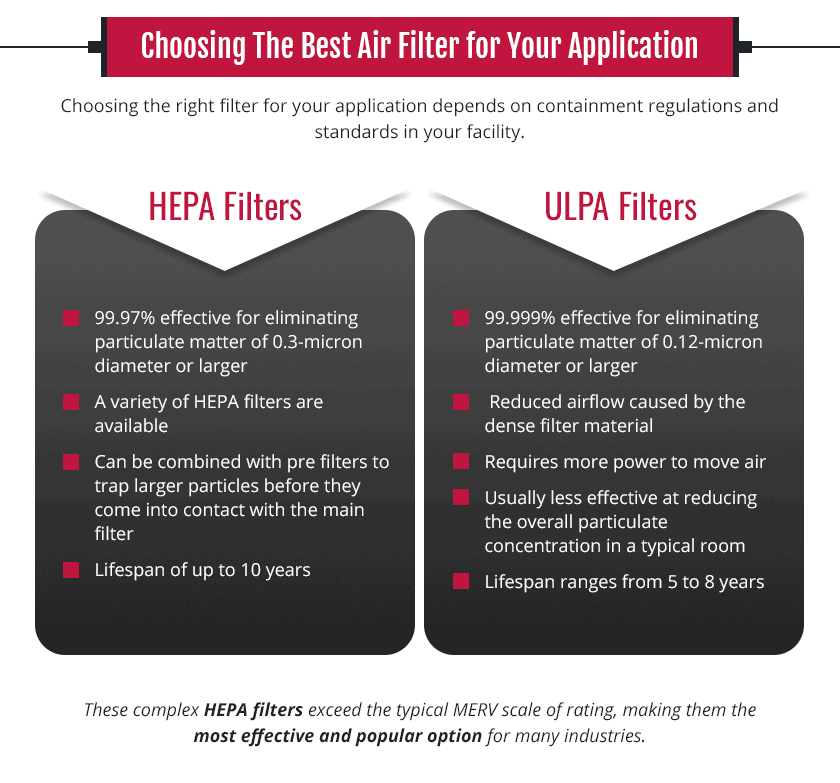

ULPA filters trap more and smaller particulate matter than HEPA filters. ULPA filters are 99.999% effective at removing submicron particulate matter of 0.12-micron diameter or larger, while HEPA filters are 99.97% effective for eliminating particulate matter of 0.3-micron diameter or larger. HEPA filters can be combined with pre filters to trap larger particles before they come into contact with the main filter.

The higher efficiency rating of the ULPA filter is due to the increased density of the filter medium, which allows airflow up to 50% lower than HEPA filters and requires more power to move air. HEPA filters have a lifespan of up to ten years, whereas the typical life cycle of an ULPA filter ranges from five to eight years. Choosing the right filter for your application depends on containment regulations and standards in your facility.

Which Air Filter is Better – ULPA or HEPA?

Filter manufacturers often stress the superior efficiency rating of ULPA filters when compared to HEPA filters. While ULPA filters trap more and smaller particulates, they are usually less effective at reducing the overall particulate concentration in a typical room than the same air filtration system equipped with HEPA filters. This is due to reduced airflow caused by the dense filter material of ULPA filters. ULPA filters typically pass 20-50% less air than HEPA filters, which results in the room having fewer air changes per hour.

There are a variety of HEPA filters available, some of which are more complex than others. These complex HEPA filters exceed the typical MERV scale of rating, making them the most effective and popular option for many industries.

Choosing the Best Air Filter for Your Application

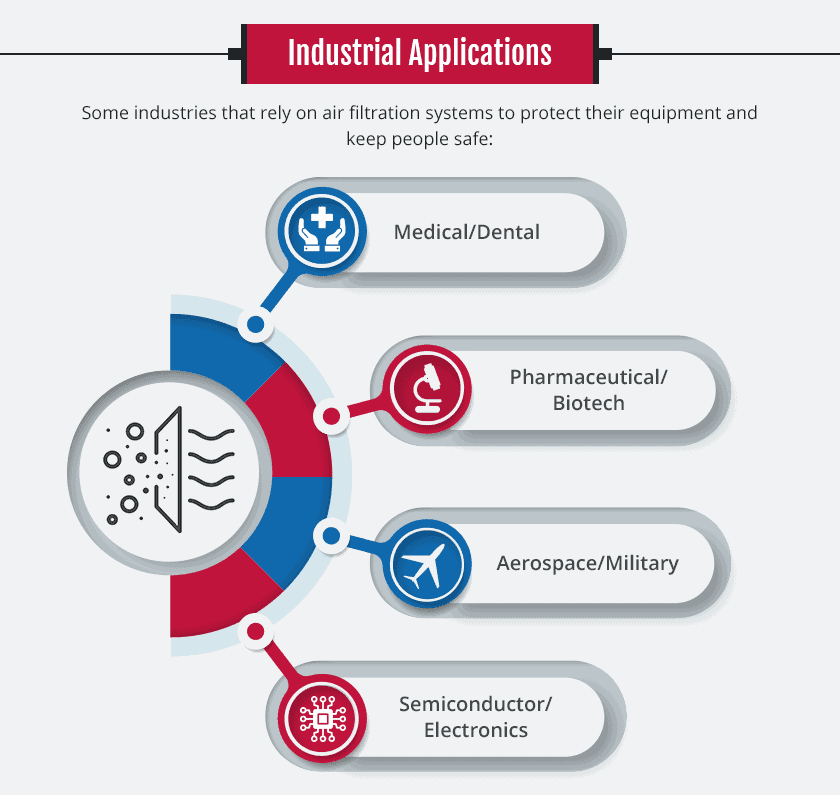

Determining the best filter for your application requires a careful analysis of your needs and any containment regulations for your facility, including the minimum number of air changes required per hour. HEPA and ULPA filters are designed for use in a variety of applications, including industrial vacuum cleaners to remove asbestos, removing toner dust from office equipment, preventing the spread of airborne bacteria in surgical operating rooms, and other crucial medical air filtration applications.

Industries such as pharmaceutical, photography, electronics, and more all rely on air filtration systems to protect their equipment and keep people safe. Understanding the requirements of your application and the level of effectiveness needed will help you choose the right air filter for your needs.

Air Filtration Solutions from Air Innovations

At Air Innovations, we are experts at designing and building air filtration systems for applications that are difficult to address with standard HVAC equipment. We specialize in creating custom solutions that meet containment regulations and any other standards required for your application. Our mission is to design and build an air filtration system that you can rely on to meet the precise tolerances and parameters you need. To request a quote for your application or to learn more about our air filtration systems, contact us today.