The military industry requires HVAC units that will perform reliably in the most demanding environments, where standard solutions are unable to fulfill application requirements. Creating controlled environments for these settings requires versatile solutions that can handle a broad range of complex environmental conditions.

At Air Innovations LLC, we provide military air conditioner solutions that are powerful, durable, and dependable. We have designed and built environmental control systems for a variety of military, aerospace, defense, and homeland security applications.

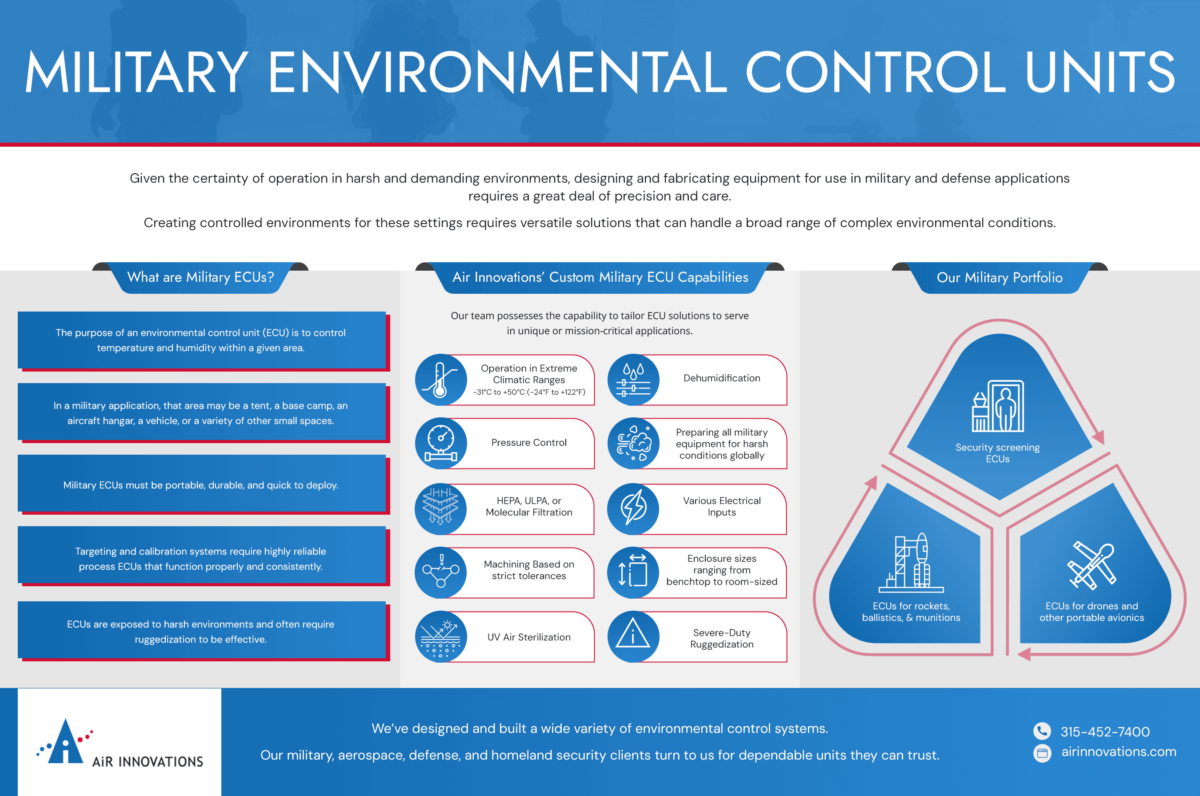

The Role of ECUs in Military Applications

The purpose of an environmental control unit (ECU) is to control temperature and humidity within a given area. In a military application, that area may be a tent, a base camp, an aircraft hangar, a vehicle, or a variety of other small spaces. This means that military ECUs must be portable, durable, and quick to deploy.

Some military and defense systems, such as targeting and calibration systems, require highly reliable process ECUs that function properly and consistently. While a commercial or industrial environmental control system shares attributes with a defense or military environmental control unit—such as having specific temperature and humidity requirements or cleanroom level filtration—many defense and military environmental control units are also exposed to harsh environments or require ruggedization to be effective.

Beyond Off-the-Shelf Military HVAC Solutions: The Air Innovations Difference

At Air Innovations, we combine advanced equipment and knowledgeable staff to develop military ECUs that meet the industry’s stringent requirements for performance, efficiency, and durability. We machine to strict tolerances, maintain consistent cleanroom production standards, and prepare military equipment for use in some of the harshest conditions around the world.

Our Military ECU Capabilities

Our Military ECU capabilities cover a range of parameters, including:

- Operation in extreme climate conditions (-24 °F to +122 ° F / -31 °C to +50 °C)

- Reliable performance in salty or coastal environments and high-humidity regions

- Pressure control

- Ultrasonic dehumidification to control relative humidity within 0.5%

- UV air sterilization (along with HEPA, ULPA, and molecular filtration options)

- Severe-duty ruggedization

Each unit can be built to handle different electrical inputs. We also offer enclosure sizes ranging from benchtop to room-sized to meet client-specific needs.

Products From our Military Portfolio

Air Innovations is an industry leader in HVAC and environmental control solutions for OEMs and end-users worldwide. Our systems are ideal for compact spaces and demanding environments. Our military portfolio contains a variety of products:

- ECUs for unmanned vehicles, such as drones and other portable avionics.

- ECUs for security screening, which are used by manufacturers of automated baggage handling explosion detection equipment.

- ECUs for aerospace that help control cleanroom conditions in spacecraft bays.

Meeting the Rigorous Demands of Military Applications

Our team at Air Innovations can build each ECU from the ground up to address the ongoing challenges of military applications, from environmental conditions to maintenance needs.

Military HVAC Systems Case Study–Withstanding Harsh Conditions

We completed a military ECU project for a defense contractor seeking more ruggedized equipment. Our client wanted ECUs that could withstand harsh field conditions such as regular use in the back of a Humvee in extreme conditions.

Our team elected to create a military ECU custom-built to tolerate temperature extremes and variations and handle unpredictable humidity. We designed the ECU in accordance with strict Mil-Spec requirements, employed strict weight and size limitations during design and packaging, and subjected the system to repeated drop testing – something rarely done in the HVAC industry. Ultimately, we provided the defense contractor with an ECU that could operate in a variety of rugged conditions and temperature extremes around the world.

Why Air Innovations?

Our team is committed to creating high-performance military HVAC systems for a wide variety of system requirements. Customers choose Air Innovations for our:

- Commitment to solving unique challenges. We continually refine and expand our designs to fulfill needs not satisfied by off-the-shelf units.

- Ability to meet unique military specifications. Our military HVAC units meet and exceed MIL-SPEC requirements for temperature and humidity control, size and weight maximums, and ruggedization.

- Adaptability and flexible processes. We manufacture specialized military ECUs that address different project parameters.

- OEM collaboration. We work with OEMs to seamlessly serve military needs.

- In-house expertise. Our teams include expert engineers, testing professionals with in-house testing facilities, and technicians with years of experience manufacturing for military applications.

- Experience across multiple industries. We have a background in aerospace, semiconductor, and other sectors with demanding applications, allowing us to bring together innovations from multiple fields into our HVAC solutions.

For more information on military environmental control units, see the case studies below: