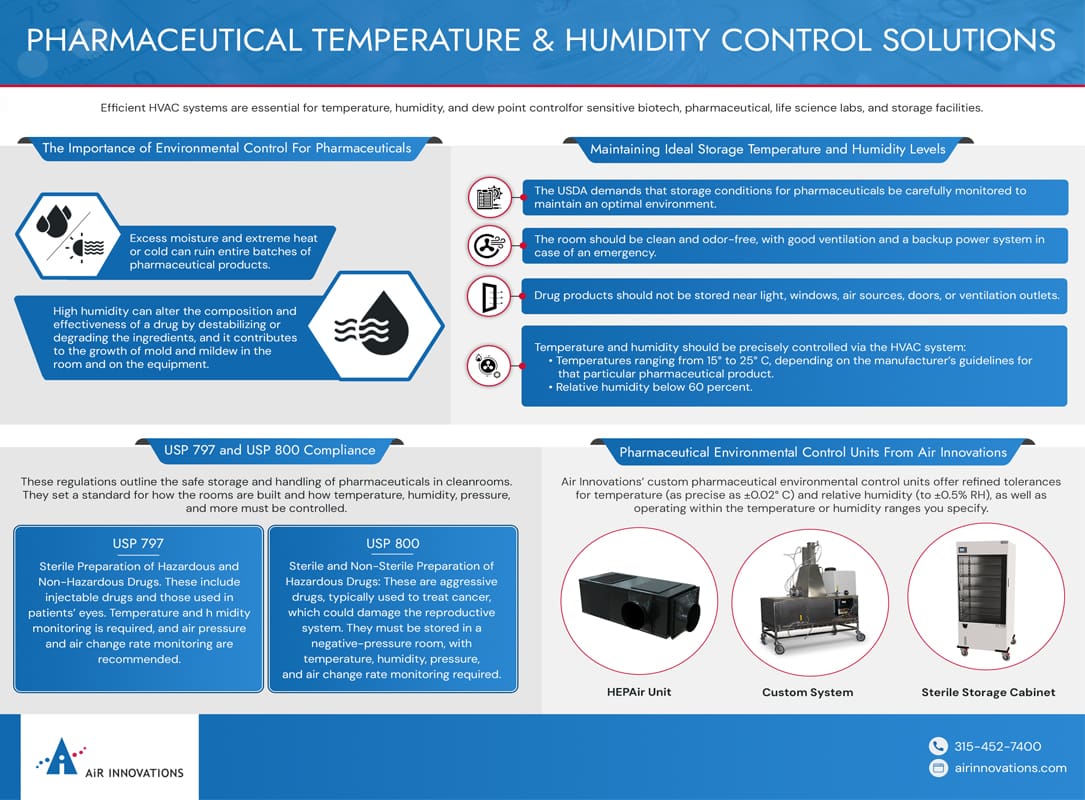

Efficient HVAC systems are essential for temperature, humidity, and dew point control for sensitive biotech, pharmaceutical, life science labs, and storage facilities. At Air Innovations, we’ve created a variety of process control systems for temperature and humidity monitoring in the pharmaceutical and biotech industries.

The Importance of Environmental Control for Pharmaceuticals and Life Sciences

Excess moisture and extreme heat or cold can ruin entire batches of pharmaceutical products. High humidity, for example, can alter the composition and effectiveness of a drug by destabilizing or degrading the ingredients, and it contributes to the growth of mold and mildew in the room and on the equipment.

Maintaining Ideal Storage Temperature and Humidity Levels

The USDA demands that storage conditions for pharmaceuticals be carefully monitored to maintain an optimal environment. The room should be clean and odor-free, with good ventilation and a backup power system in case of an emergency. Drug products should not be stored near light, windows, air sources, doors, or ventilation outlets. Temperature and humidity should be precisely controlled via the HVAC system:

- Temperatures ranging from 15° to 25° C, depending on the manufacturer’s guidelines for that particular pharmaceutical product

USP 797 and USP 800 Compliance: Pharmacy HVAC Systems

These regulations outline the safe storage and handling of pharmaceuticals in cleanrooms. They set a standard for how the rooms are built and how temperature, humidity, pressure, and more must be controlled.

- Relative humidity below 60 percent

- USP 797: Sterile Preparation of Hazardous and Non-Hazardous Drugs. These include injectable drugs and those used in patients’ eyes. Temperature and humidity monitoring is required, and air pressure and air change rate monitoring are recommended.

- USP 800: Sterile and Non-Sterile Preparation of Hazardous Drugs: These are aggressive drugs, typically used to treat cancer, which could damage the reproductive system. They must be stored in a negative-pressure room, with temperature, humidity, pressure, and air change rate monitoring required.

An effective HVAC system designed for use in a pharmaceutical environment is essential to remain compliant with these standards.

Pharmaceutical Environmental Control Units from Air Innovations

The temperature and humidity control units used in pharmaceutical environments have to meet specific construction requirements. This could include the materials: some environments may require stainless steel construction or coated aluminum because of the particular sterilization processes used in that room and how the materials react to those processes. For example, stainless steel units may be required in certain applications that use vaporized hydrogen peroxide (VHP) sterilization.

Size is another consideration. Many research and development spaces and compounding pharmacies aren’t very big, and they may need a temperature and humidity regulation solution that accommodates that smaller space. While many HVAC systems can work in either sterile or non-sterile spaces, there are specific solutions for each design.

Air Innovations’ custom pharmaceutical environmental control units offer refined tolerances for temperature (as precise as ±0.02° C) and relative humidity (to ±0.5% RH), as well as operating within the temperature or humidity ranges you specify. To learn more about how HVAC systems can be designed to meet the stringent requirements of pharmaceutical cleanrooms, download our life sciences white paper, A Healthy Environment.

We can design, test, and build products that can be incorporated into or run in parallel with your existing system. From an integrated environmental control system for chemical process control and pharmaceutical HVAC systems running in tandem with fluid-bed dryers and blister packing machines to a Class 1 Div. 1 explosion-proof HVAC unit that controls the process air needed for solvent-based coating of pharmaceutical tablets, we have extensive experience in temperature and humidity monitoring in the pharmaceutical industry.

STANDARD PRODUCTS:

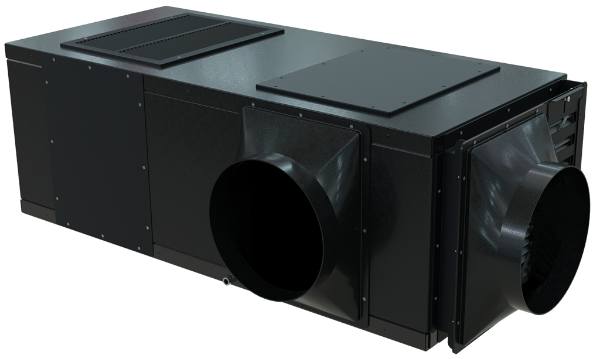

HEPAir Cleanroom HVAC systems are the perfect solution for stable control of temperatures, humidity, pressure and cleanliness. Features include:

- Operates independently of large, central systems

- Can control positive and negative pressure

- Designed for once-through or recirculating applications

- Designed to match to most existing fan/filter units

ArrayAir Cleanroom HHVAC units are portable solutions specially designed to maintain exact clean room humidity, stable temperature and cleanliness in a clean room environment up to 30 cubic feet. Features include:

- Thermal electric cooling 162 watts

- Humidifies up to 80% RH

- Dehumidifies down to 10% RH

- Fan speed control

- Heating capacity 300 watts

- Custom units available

Custom Products:

Air Innovations has designed and manufactured custom environmental control products for a variety of biotechnology, life science, and pharmaceutical applications. One integrated system we designed regulated humidity and temperature for protecting onboard process reagents. Another medical environmental control system was designed for desiccant humidity set to <3% RH ±0.5% and temperature regulation. Still other systems were designed with these features:

- HEPA or chemical air filtration, positive external pressure, UV sterilization, or ultrasonic humidification.

Our capabilities include temperature control tolerances from plus or minus a few degrees to 0.02°C and humidity control to +/-0.5% RH

Contact Our Experts for Custom Temperature & Humidity Control Solutions

Since 1986, Air Innovations has valued ongoing growth and improvement, a commitment that has allowed us to serve clients in a wide range of industries working under the strictest standards. We maintain a dedicated research and development department to test our engineered solutions. Our goal is to help our clients find the most effective, cost-efficient solution to their humidity and temperature control challenges.

Over the years, we’ve worked extensively with clients in the pharmaceutical, healthcare, and research industries, along with military, semiconductor, aerospace clients, and more. We have an in-depth understanding of industry standards and requirements, and we collaborate with our clients to find the ideal solution for their unique application. Contact us to learn more about temperature and humidity monitoring in the pharmaceutical industry, or to request a quote for your project.

Contact Our Team TodayFor more information on aerospace environmental control systems, read the case studies below: