HVAC systems are essential components in the functionality and appeal of all modern buildings. Well-designed and efficient HVAC systems go well beyond ensuring comfortable temperatures and fresh air for facilities. They also play a key role in the production and testing processes of a broad spectrum of industries.

HVAC systems play a crucial role in pharmaceutical engineering and manufacturing because they have a direct impact on the production environment. Optimized HVAC units can help pharmaceutical companies Mining and Drilling, pass inspections, and remain CGMP-compliant, and more.

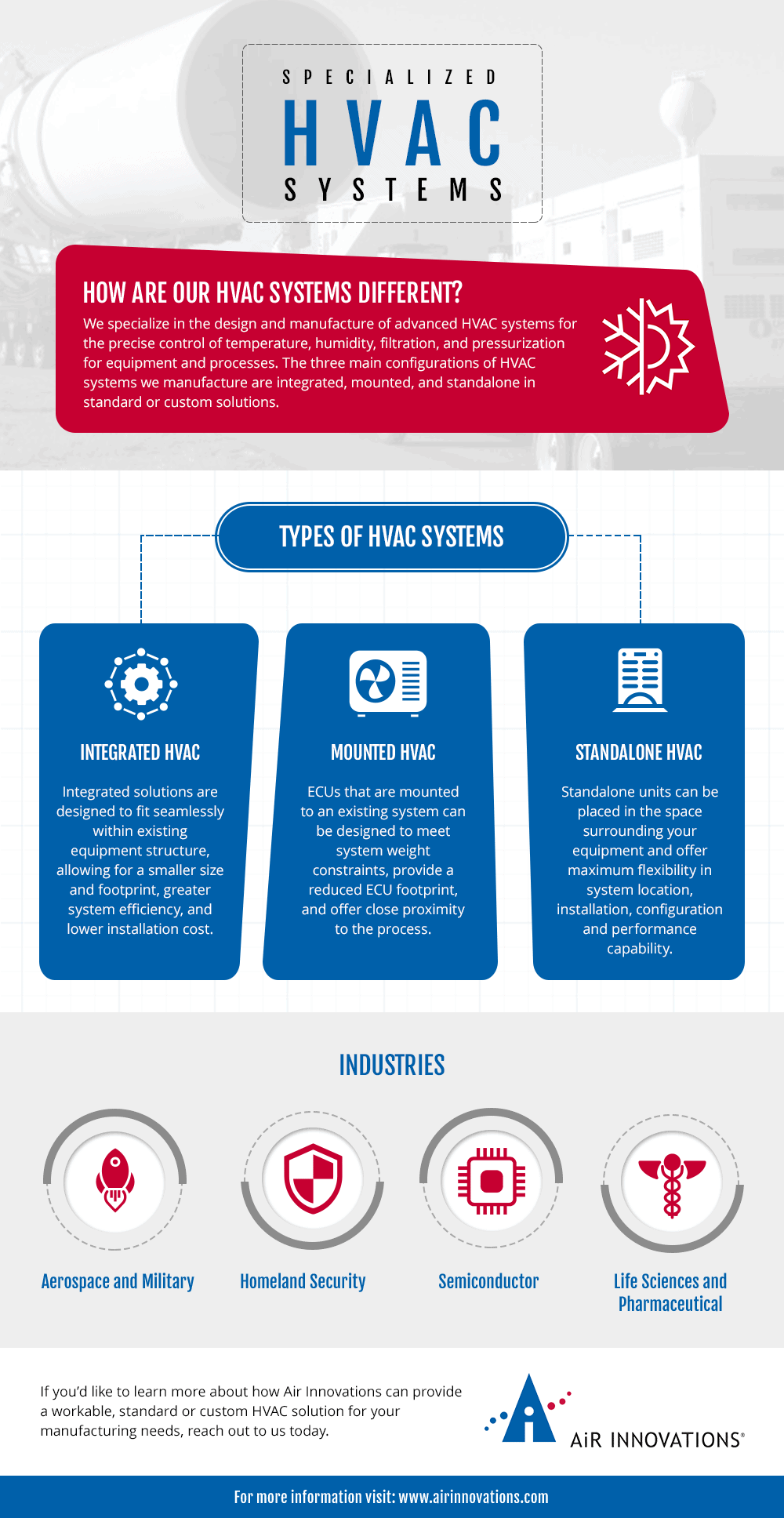

All You Need to Know About Specialized HVAC Systems

What is a Specialized HVAC System?

The acronym HVAC stands for heating, ventilation, and air conditioning. Specialized HVAC systems control the temperature, humidity level, and air quality in a space to ensure the required specifications for your application are met.

Types of HVAC Systems We Design & Manufacture

We specialize in the design and manufacture of advanced HVAC systems for the precise control of temperature, humidity, filtration, and pressurization for equipment and processes. The three main configurations of HVAC systems we manufacture are integrated, mounted, and standalone in standard or custom solutions.

Integrated HVAC

Integrated solutions are designed to fit seamlessly within existing equipment structure, allowing for a smaller size and footprint, greater system efficiency, and lower installation cost.

Mounted HVAC

ECUs that are mounted to an existing system can be designed to meet system weight constraints, provide a reduced ECU footprint, and offer close proximity to the process.

Standalone HVAC

Standalone units can be placed in the space surrounding your equipment and offer maximum flexibility in system location, installation, configuration, and performance capability.

Explosion-Proof HVAC

Less common but no less critical, explosion-proof HVAC systems are an essential aspect of many industrial applications. For example, ore mining/processing facilities can make use of these units to prevent an explosion of coal dust particles in the air.

Other industries that utilize explosion-proof HVAC systems include:

- Oil and gas

- Military

- Aerospace

- Pharmaceuticals

- Food processing

- Agriculture

Nowadays, many off-the-shelf explosion-proof units are available. However, companies that require explosion-proof environmental control units often need to ensure that their HVAC systems supplier has the capability to provide a tailored solution for their particular application.

Industries and Applications

Industries ranging from homeland security to aerospace use specialized HVAC solutions as an essential part of their daily operations. The following are some examples of specific industries and applications that utilize HVAC systems.

Aerospace

Aerospace applications require strict environmental control in everything from research and development to launch areas. At Air Innovations, we’ve supported a variety of unique aerospace projects, such as clean room filtration, environmentally controlled transportation of aerospace components, and strict environmental control of launch areas.

For example, one rocket’s fueling system demanded a dry dew point of -22° C just before launch. Any remaining moisture would condense and transform into ice on the rocket’s piping, creating a dangerous situation. The solution to this quandary was an in-line desiccant dryer surrounded by two tailored environmental control units used to eliminate moisture and maintain tight temperature tolerances.

Homeland Security

Durable HVAC units assist in temperature and humidity maintenance at airport terminals, including security checkpoints and baggage claim areas. Additionally, explosives detection devices (EDDs) at airports demand strict internal control of temperature and humidity variables in order to function properly.As such, the Homeland Security Department relies on specialized HVAC units for these applications.

Mining and Drilling

Mining and drilling companies use environmental control units to keep electrical cabinets of centrifuge machines cool. Centrifuges eliminate slurry during drilling operations, and are therefore an indispensable component of the overall extraction process. ECUs that keep their cabinets cool help prevent overheating, fires, explosions, and other dangerous circumstances.

Life Sciences and Pharmaceutical

Biotech and pharmaceutical companies frequently employ specialized HVAC units for strict control over temperature, humidity, and dew point, especially when handling sensitive equipment, or performing processes that require certain environmental conditions to succeed.

Cleanroom

Computer rooms, laboratories, hospitals, and process isolators often make use of cleanrooms. HVAC units designed for cleanroom use often come with features such as positive/negative pressure control, once-through or recirculating air flow, and alarms triggered by the slightest variance from set tolerances.

The Pharmaceutical Industry and HVAC Systems

The Importance of HVAC Systems for the Pharmaceutical Industry

Why are well-functioning HVAC systems so important to the pharmaceutical industry today? While there are many factors involved, but here are just two of the reasons they are so essential:

- Modern diagnostic machines need to operate within very strict temperature and humidity tolerances so that the integrity of powdered and fluid reagents is not comprised. The consequences of a misdiagnosis or false reading from the introduction of unanticipated moisture, for example, could be serious for both patient and medical provider alike. Customized HVAC units that ensure stable environmental conditions—whether cold, hot, or dry—and integrate well into often limited space, are key pieces of an effective diagnostic process.

- Moisture can be one of the worst enemies of modern medicine production. In every phase of production—from milling to compounding to coating—excess moisture can cause manufacturing inefficiencies, weaken the medicine’s effect, or in the worst-case scenario, completely ruin an entire batch of product. Specialized HVAC units that enforce a specified dew point based on the application all but guarantee that there will be no excess moisture from the air to cause production issues.

System Design

There are several design considerations that engineers must apply to HVAC systems intended for pharmaceutical applications. Ideally, architectural components should dovetail with HVAC design factors, such as pressure differential cascades and cross-contamination control. Adequate ventilation and filtration are important considerations for laboratory testing areas and cleanrooms.

Additionally, HVAC engineers must implement systems that ensure strict control over temperature, relative humidity and/or dew point, without interfering with the actual pharmaceutical manufacturing process.

Operational HVAC Optimization in Pharmaceutical Facilities

After HVAC room requirements have been established, there are ways to optimize HVAC system operations to keep costs low and efficiencies high. Some optimization measures could include:

- The reduction of air-change rates

- Optimized temperature and humidity limits

- Improved control sequences for use of floating set-points and dead-band control

- Changeover to a two-port variable volume system

- The addition of airflow meters and air volume control components

Efficient and Custom HVAC Solutions at Air Innovations

Air Innovations provides several HVAC products specifically designed for use in the pharmaceutical industry. These include:

- HEPAir Cleanroom HVAC Units

- ArrayAir portable systems

- Medical Device ECUs

- Medical Environmental Control Systems with Desiccant Humidity Control and Temperature Control

- Customized environmental systems

Some Case Studies

Air Innovations has enjoyed much success in delivering highly specialized HVAC solutions to clients in the pharmaceutical industry.

For example, one customer requested a precision control HVAC system to provide uniform drying for fluid bed dryers used in capsule and pill coating. Air Innovations supplied a pharmaceutical process control unit that provided airflow to the process tools, allowed the client to add or remove humidity, and maintained a steady dew point of 50° F.

In another case, a client needed a chemical process control unit that would hold set temperature and humidity levels in widely varying conditions all over the globe, while also operating on a continuous, year-round basis. Air Innovations provided an HVAC unit that depends on two independent cooling coils, along with process fans that alternate operation time. Various sensor inputs help to manage switch-over intervals. As a result, the cooling coils continue running without defrost interruptions, even in sub-zero temperatures.

HVAC systems are an essential aspect of pharmaceutical manufacturing. If you’d like to learn more about how Air Innovations can provide a workable, highly-customized, and efficient HVAC solution for your manufacturing needs, reach out to us today.