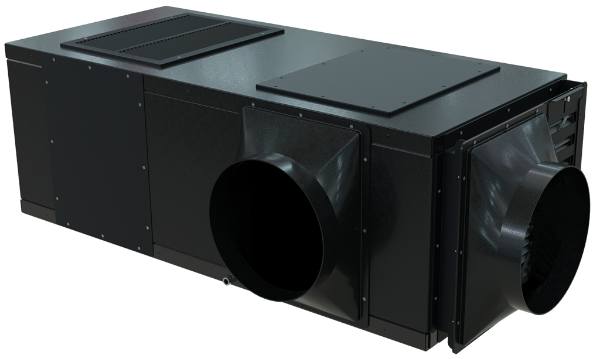

Businesses across industries need HVAC to regulate the conditions in their facilities, but HVAC systems are not always one-size-fits-all. Particularly in challenging environments or demanding applications, off-the-shelf HVAC and Environmental Control Units (ECUs) often fail to meet precise requirements. Whether you need temperature stability, humidity control, or specialized air filtration, finding a tailored solution is critical.

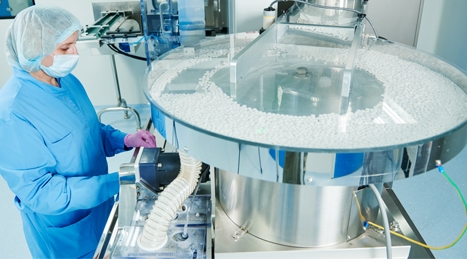

As a leading custom HVAC manufacturer, Air Innovations offers full-service capabilities in HVAC design, prototyping, and production. Our team specializes in delivering custom HVAC systems and ECUs engineered to meet unique environmental challenges within the medical, aerospace, military, and industrial sectors. Here, we’ll explore our comprehensive capabilities and how our end-to-end approach can benefit your business.

Air Innovations: Mastering Environmental Control, Start to Finish

At Air Innovations, we take a comprehensive approach to custom HVAC design, ensuring every product meets your exact needs. Our process starts with a deep understanding of your specific climate control requirements. We collaborate with you to assess environmental factors, application constraints, and performance expectations before our expert team of engineers develops a tailored solution. Unlike most off-the-shelf products, our custom HVAC units are optimized for precise temperature regulation, humidity control, air filtration, and pressurization to ensure they meet the demands of your industry.

Once the initial design is finalized, we move to prototyping and rigorous testing in our advanced, in-house psychrometric facility. This process ensures that every unit will meet the required specifications prior to production.

Why Partner with Air Innovations?

- Full-Service Expertise. From design to final production, we handle everything in-house.

- Warranty-Backed Services. Our custom HVAC and ECU services are backed by warranty support and a commitment to customer satisfaction.

- Industry Compliance. Our products meet safety and performance standards, including ETL, CCC, CSA, UL, CE, SEMI, ANSI, and MIL-STD.

- Lean Manufacturing. Our entire technical staff is cross-trained across all products, following lean manufacturing principles for faster production times.

Identify Your Needs

Begin by determining the specifications for your custom environmental control system. Consider the temperature control, humidity regulation, filtration, and pressurization requirements of your application. Other factors to consider may include:

- Unit sizing

- Integrated, mounted or standalone configuration

- Stationary or mobile design

- Operational environment

- Mil-Spec, Semi, or other industry standards

- Explosion-proof capabilities

Design / Simulation

Once the parameters of your system have been identified, our team of expert engineers will begin developing a system to meet your application requirements. Before moving into production, we run simulations to test and refine the system’s design.

Manufacturing

Custom one-off systems and prototype units, like all our cooling systems, are assembled in our facility in the USA from durable, high-quality components. Our team of qualified HVAC technicians will construct the unit exactly to the engineered specifications.

Testing

Once a prototype or custom one-off system is assembled, it is rigorously tested in our in-house psychrometric facility to ensure it meets your application demands and complies with industry standards such as AHAM, AHRI, and ASHRAE. Our dual-chamber test lab allows us to test system functionality in a variety of conditions so we can identify issues and make necessary refinements.

Shipping & Startup

After any design changes are implemented and re-tested, we’ll ship the unit directly to your facility. The Air Innovations team will be standing by after delivery to offer installation and startup support or to facilitate the production of additional units.

HVAC Design, Prototyping & Production: Our Comprehensive Approach

Air Innovations’ comprehensive approach to HVAC and ECU development follows these main steps:

2. Prototyping & Testing: Ensuring Performance and Reliability

At Air Innovations, we maintain a dedicated R&D department to create, test, and validate our customized systems. Before production begins, we create a prototype of your design, which is rigorously tested in our in-house psychrometric testing chamber. Doing this allows us to confirm system performance under real-world conditions and make necessary refinements.

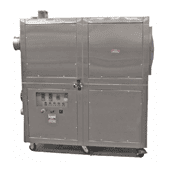

3. Precise HVAC Manufacturing

Once your design is tested and validated, we can move to manufacturing. At Air Innovations, we can handle both one-off custom solutions and large-scale repeat builds. Whether you have strict size or shape requirements, require an explosion-proof solution, or need precise microbial control, our team of experts can produce the ideal system. With decades of experience, we can manufacture custom HVAC units that meet the most challenging specifications.

Identify Your Environmental Control Needs

Begin by identifying your environmental control needs:

- Temperature Control. Our systems provide precise temperature control in environments ranging from -20°F to 125°F (-29°C to 52°C).

- Humidity Regulation. Our systems can accurately control humidity and dew point to ensure proper moisture levels for your environment.

- Filtration. Our systems can be tailored to meet your filtration needs, with options for molecular, ULPA, and HEPA filters.

- Pressurization. Our HVAC systems and ECUs can be designed for both positive and negative pressurization.

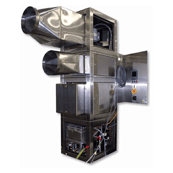

Determine the Right ECU Configuration

To meet varying application requirements, our custom ECUs are available in three main configurations:

- Integrated. Integrated units accommodate your existing equipment structures, resulting in improved efficiency, reduced installation costs, and a smaller footprint.

- Mounted. Mounted units attach to existing systems, reducing their overall footprint and weight.

- Standalone. Standalone units are installed around equipment, allowing for improved flexibility and performance capabilities.

Choose Features and Customization Options

Our HVAC systems and ECUs can include various features and customization options, including:

- Custom sizing and configurations

- Stationary or mobile units

- UV sterilization

- Up to 5,000 CFM

- Explosion-proof capabilities

- DX, thermoelectric, or chilled water cooling

- MIL-SPEC or SEMI standards

- Cooling capacity ranging from 3,000 to 180,000 BTU/h

Project Design and Quote

Once your system requirements are defined, our team provides a detailed project design and quote that aligns with your goals and budget.

Custom Environmental Control Units

Learn more about “Custom Environmental Control Units” eBook

Featured Case Studies: Proven Success

Companies across of the world have trusted Air Innovations to deliver solutions for their environmental control challenges. Learn how we do it.

View All Case StudiesYour Partner in Custom HVAC Solutions

Ready to create a custom HVAC system that fits your unique needs? Air Innovations has the expertise and technology to deliver a climate control solution that exceeds expectations. Contact us today to get started!

Let's Get in Touch

For info on tabletop humidifiers labeled “Air Innovations”

QVC, The Home Depot, and other retailers sell some consumer products, like tabletop humidifiers, labeled “Air Innovations” that are not affiliated with our company, Air Innovations LLC. We sell environmental control equipment for businesses. Please contact the manufacturer’s customer service at 1-844-600-1370 with any questions about your product.

For info on tabletop humidifiers labeled “Air Innovations”

QVC, The Home Depot, and other retailers sell some consumer products, like tabletop humidifiers, labeled “Air Innovations” that are not affiliated with our company, Air Innovations LLC. We sell environmental control equipment for businesses. Please contact the manufacturer’s customer service at 1-844-600-1370 with any questions about your product.